Valve Manufacturing Methods & Processes Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

As part of our comprehensive Valve and Actuation Training programme, our Manufacturing Methods course delivers fundamental education designed to understand how valve construction affects performance, reliability, and application suitability. This technical course focuses on casting versus forging processes, material properties, and quality implications, providing participants with the expertise needed to make informed decisions about valve selection based on manufacturing methods and their impact on service life.

To learn more about what to expect as part of this training course, view the table below. If you are interested in taking part in our next training session, fill out the nearby contact form.

Agenda

Introduction to Manufacturing Methods

Overview of valve manufacturing processes, understanding material malleability constraints, and the fundamental differences between casting and forging approaches.

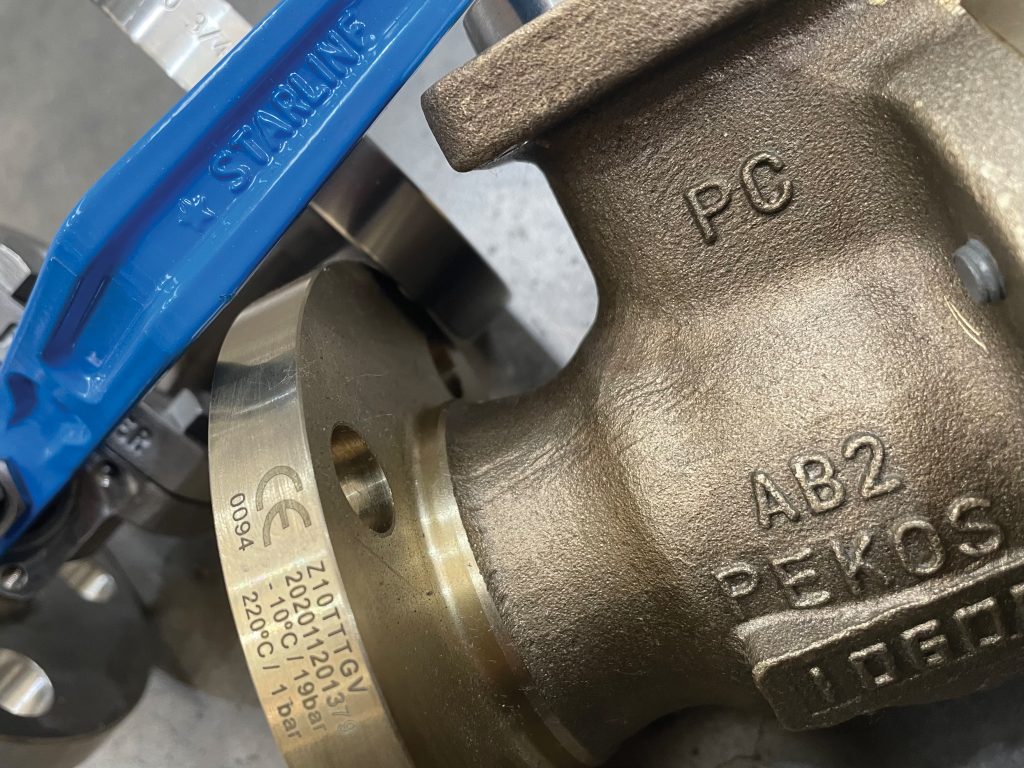

Cast Valve Production

Examination of lost wax method and casting with formers, understanding complex shape capabilities, material wastage considerations, and quality characteristics of cast components.

Forged Valve Manufacturing

Analysis of closed die forging processes, grain structure benefits, and the transition to ring forging for larger valve sizes, including strength and pressure capability advantages.

Material Properties and Performance

Comparison of mechanical qualities between cast and forged materials, understanding grain structure effects, and how manufacturing methods influence pressure and temperature ratings.

Common Material Specifications

Review of ASTM standards for cast materials (A216 WCC, A351 LCC, A351 CF8M, GGG40) and forged materials (A105N, A350 LF2, A182 series), including temperature limitations.

Quality and Structural Considerations

Understanding impurity risks, bubble formation, structural integrity differences, and how manufacturing methods affect valve reliability and maintenance requirements.

Cost and Application Trade-offs

Analysis of cost implications, size limitations, shape complexity constraints, and selecting appropriate manufacturing methods for specific service conditions.

By the end of the course, participants will confidently evaluate whether cast or forged valves are appropriate for specific applications, understand how manufacturing methods affect pressure and temperature capabilities, and recognise quality indicators that impact valve performance. This expertise will enable you to make cost-effective material selections whilst ensuring reliability requirements are met, understand why certain valves are limited in size or pressure rating, and communicate manufacturing considerations effectively when specifying valves in your engineering or procurement role.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification