Triple Offset Butterfly Valves Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

As part of our comprehensive Valve and Actuation Training programme, our Triple Offset Butterfly Valves course delivers specialised education designed to understand advanced butterfly valve technology and its industrial applications. This technical course focuses on the unique triple offset design principles, high-pressure capabilities, and specialised seating systems, providing participants with the expertise needed to specify and maintain these sophisticated valves in demanding process environments.

To learn more about what to expect as part of this training course, view the table below. If you are interested in taking part in our next training session, fill out the nearby contact form.

Agenda

Introduction to Triple Offset Technology

Overview of triple offset butterfly valve principles, comparing design approaches and understanding the three offset axes that minimise wear and friction.

Design and Construction Principles

Examination of the coned profile machining, camming action mechanics, and the difference between flexible body seats versus flexible disc seat designs using Zwick technology.

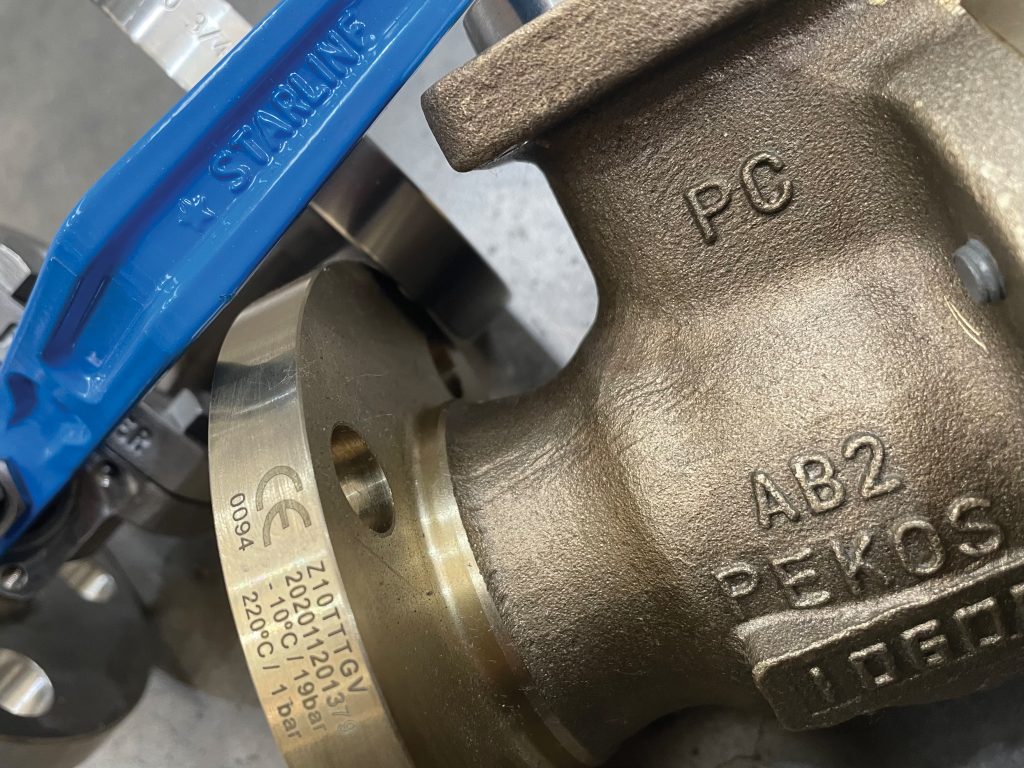

Materials and Seating Systems

Analysis of laminated seat construction combining stainless steel and graphite, body seat materials including 316 Ti and Stellite options, and shaft material specifications.

High-Pressure Capabilities

Understanding pressure ratings up to Class 900/PN150, material strengthening requirements, and the advantages of metal-to-metal seating over polymer-based systems.

Operational Characteristics

Exploration of minimal contact operation, positioning requirements, lockable levers, gearbox considerations, and actuator drive coupling with offset mechanisms.

Body Configuration Options

Review of different body styles including butt-weld, wafer pattern, through lugged, fully lugged, double flanged, and double block and bleed configurations.

Control Applications and Specialised Designs

Discussion of control valve capabilities, Tri-Shark design features, and application considerations for oil and gas, chemical processing, and power generation industries.

By the end of the course, participants will confidently specify triple offset butterfly valves for high-pressure and high-temperature applications, understand the critical importance of proper machining and assembly, and evaluate appropriate body configurations for different installation requirements. This expertise will enable you to select cost-effective alternatives to ball valves in demanding applications, specify appropriate materials for corrosive and abrasive services, and understand maintenance requirements that extend valve life in your engineering or operations role.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification