Seats and Seals Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

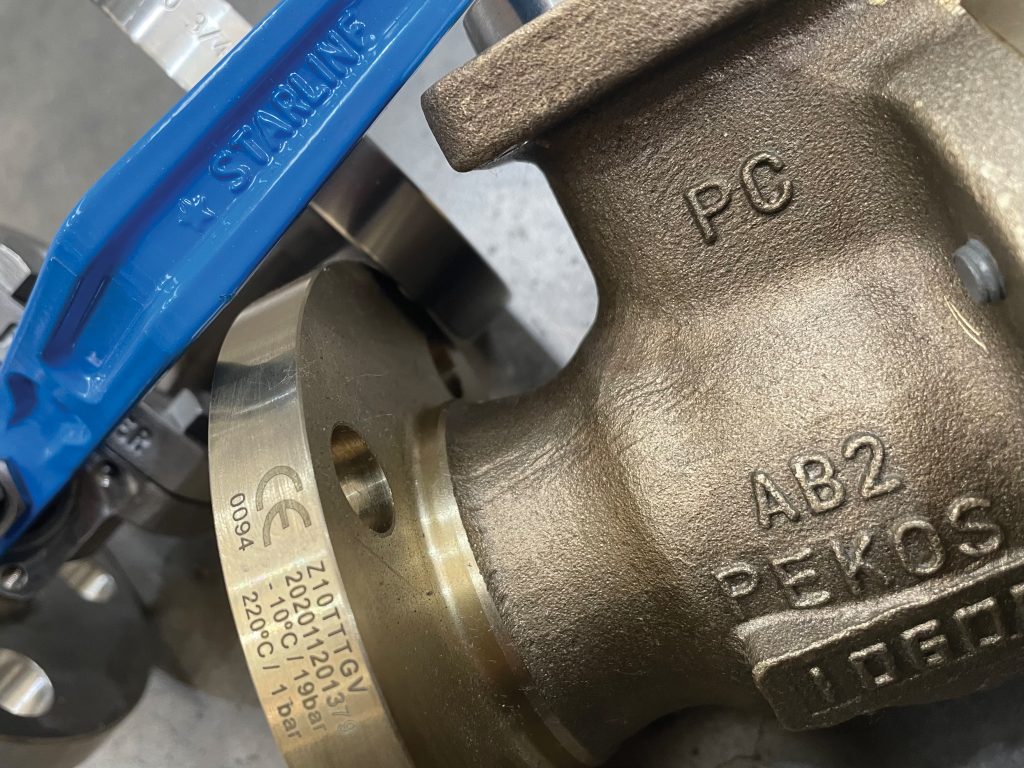

As part of our comprehensive Valve and Actuation Training programme, our Seats and Seals for Ball Valves course delivers essential education designed to understand material selection across all pressure classes and service conditions. This specialised course focuses on seat and seal technologies from low pressure PTFE variants through to high pressure advanced materials, providing participants with the expertise needed to specify appropriate materials, prevent costly failures, and optimise valve performance in critical applications.

To learn more about what to expect as part of this training course, view the table below. If you are interested in taking part in our next training session, fill out the nearby contact form.

Agenda

Introduction to Seat and Seal Functions

Overview of how seats and seals determine valve performance, understanding the relationship between seat materials and pressure/temperature ratings, and the importance of material matching.

Low Pressure Materials Foundation

Examination of virgin PTFE/TFM, reinforced PTFE variants with fibreglass, carbon/graphite, and metal reinforcement, including temperature ranges and pressure limitations up to Class 900.

Specialised Low Pressure Applications

Analysis of UHMWPE for radiation and tobacco service, graphite for fire-safe applications, and understanding when chemical compatibility becomes critical for material selection.

High Pressure Material Technologies

Understanding materials beyond Class 900 limitations, including Devlon V Grade Nylon, Kel'F (PCTFE) for cryogenic service, and PEEK for extreme pressure applications up to Class 2500.

Material Selection and Trade-offs

Evaluation of hardness versus sealing capability, the need for backing washers with harder materials, torque implications, and cost versus performance considerations across all pressure classes.

Manufacturing and Assembly Considerations

Understanding lapping procedures for hard seats, retrofit challenges, quality testing requirements, and how seat hardness affects valve assembly and maintenance.

Application-Specific Material Matching

Practical guidance on selecting materials for steam service, cryogenic applications, abrasive duties, chemically aggressive environments, and food-grade requirements.

By the end of the course, participants will confidently select appropriate seat and seal materials for any pressure class and service condition, understand the critical relationship between material hardness and sealing performance, and evaluate cost versus performance trade-offs across the full range of available materials. This expertise will enable you to prevent costly specification errors, avoid material failures in extreme service conditions, reduce maintenance issues through proper material selection, and make informed procurement decisions that balance technical requirements with budget constraints in your engineering or operations role.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification