Floating Ball Valve Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

This course provides a comprehensive understanding of Floating Ball Valves, focusing on their design principles, operational mechanisms, advantages, limitations and practical applications in various industrial sectors. Floating Ball Valves play a critical role in ensuring tight shutoff and flow control in pipelines, particularly in gas and oil processing.

Trainees will explore how these valves function under different pressure conditions, how they are assembled and why they are preferred in certain scenarios. Through a mix of theory, design analysis and practical considerations, participants will gain valuable insights into troubleshooting, valve selection and installation.

Agenda

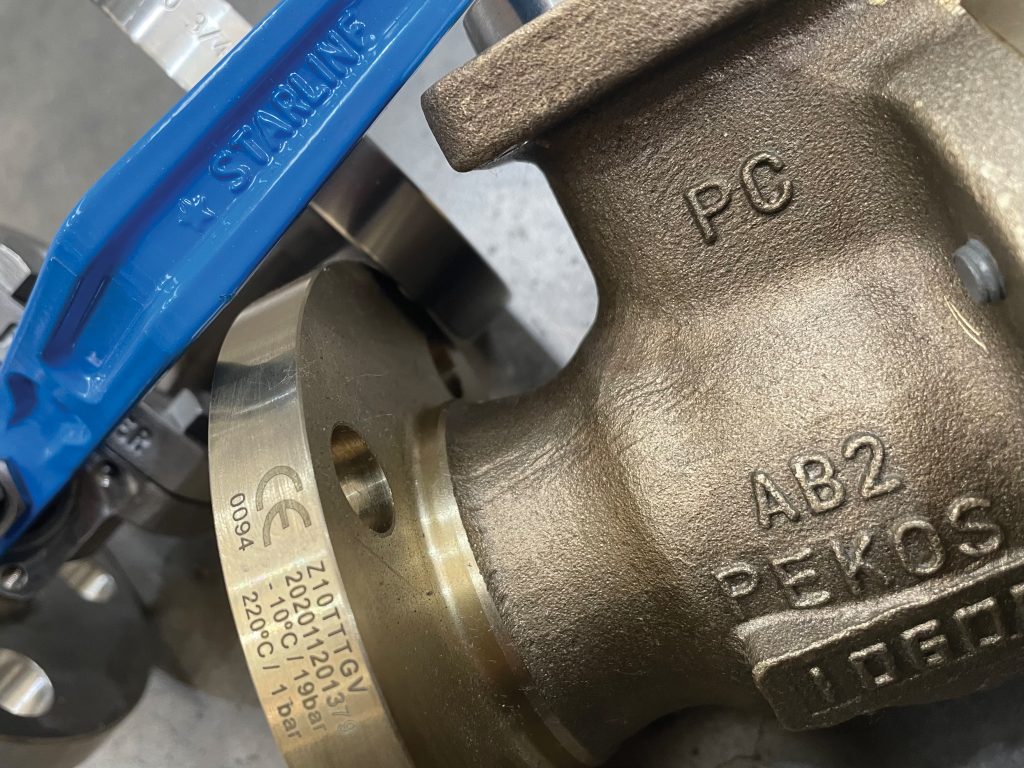

Introduction to Floating Ball Valves

Overview of different valve types, focusing on the characteristics that distinguish Floating Ball Valves.

Design Principles

Exploration of the floating ball mechanism, including pre-load design and how it contributes to sealing capabilities.

Operational Characteristics

Understanding the quarter-turn operation, blowout-proof stem design and the implications for safety and efficiency.

Material Selection

Examination of materials used in Floating Ball Valves, discussing their compatibility with various media and potential vulnerabilities.

Performance Factors

Insights into pressure ratings, valve design limits and how line pressure affects sealing performance.

Advantages and Disadvantages

In-depth discussion of the key benefits of Floating Ball Valves, as well as potential challenges and limitations in different applications.

Practical Applications

Analysis of typical industry applications, supported by case studies that highlight successful implementations of Floating Ball Valves.

Industry Standards and Testing

Overview of relevant industry standards such as NACE, fire-safe requirements and anti-static measures, along with compliance testing methods.

By the end of the course, participants will confidently identify appropriate valve types for specific applications, specify correct pressure classes and materials, and recognise critical safety requirements. This knowledge will enhance your ability to make informed procurement decisions, reduce specification errors, and improve system reliability in your operational role. You’ll also develop troubleshooting skills that enable faster problem resolution and more effective communication with suppliers and maintenance teams.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification