Concentric and Double Offset Butterfly Valves Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

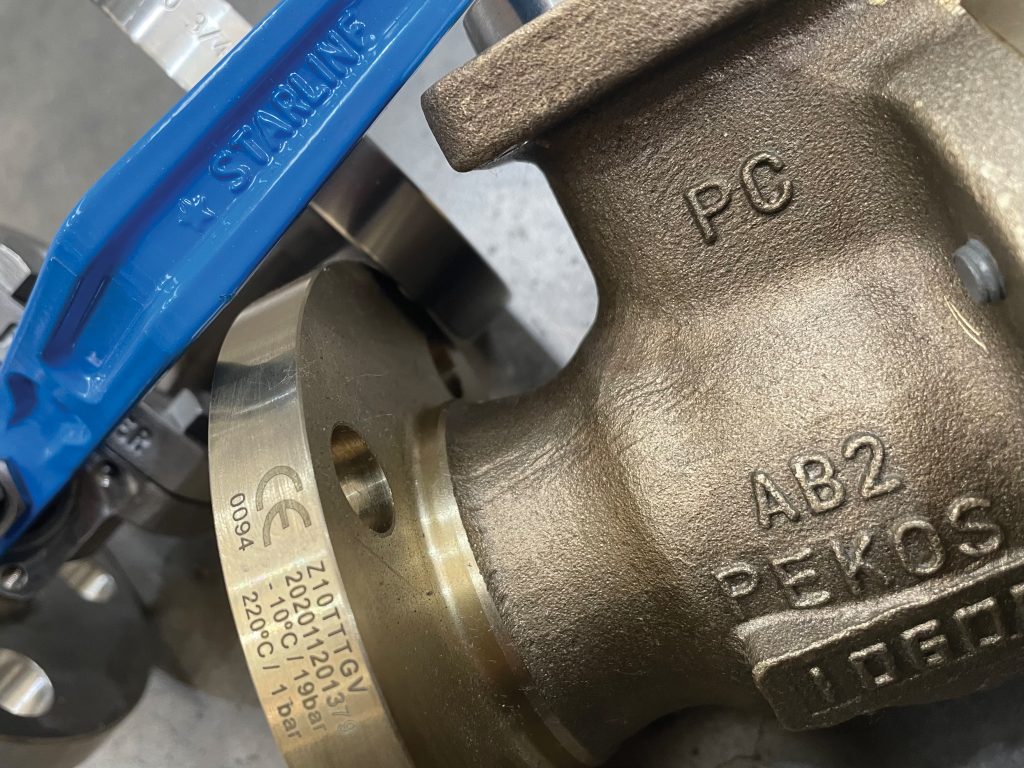

As part of our comprehensive Valve and Actuation Training programme, our Concentric and Double Offset Butterfly Valves course delivers specialised education designed to understand the fundamental differences between these two butterfly valve technologies and their appropriate applications. This technical course focuses on design principles, seating systems, and performance characteristics, providing participants with the expertise needed to select the correct butterfly valve type for specific service conditions and understand their operational limitations.

To learn more about what to expect as part of this training course, view the table below. If you are interested in taking part in our next training session, fill out the nearby contact form.

Agenda

Introduction to Butterfly Valve Technologies

Overview of butterfly valve principles, comparing concentric versus double offset designs, and understanding how disc positioning affects performance and contact wear.

Concentric Butterfly Valve Design

Examination of shared centreline construction, rubber liner functions including body isolation and stem sealing, and the role of vulcanised versus cartridge liner systems.

Double Offset Design Principles

Analysis of dual offset positioning, camming action mechanics, and how offset geometry reduces seat contact from 5° to 1-3° during operation cycles.

Seating Systems and Materials

Comparison of rubber liner limitations versus PTFE/reinforced PTFE seats, understanding energised seat designs with metal backing springs, and fire-safe considerations.

Performance Characteristics and Limitations

Evaluation of pressure and temperature ratings, flow coefficient comparisons, torque characteristics including break-open/end-close requirements, and application-specific constraints.

Installation and Mounting Considerations

Understanding wafer pattern configurations, direct mounting capabilities for concentric designs, bracket requirements for double offset valves, and face-to-face dimension standards.

Application Selection Criteria

Analysis of when to specify concentric valves for low-pressure hygienic applications versus double offset valves for higher pressure industrial service, including cost and maintenance considerations.

By the end of the course, participants will confidently distinguish between concentric and double offset butterfly valve applications, understand the critical importance of liner versus seat selection, and evaluate pressure, temperature, and chemical compatibility limitations for each design. This expertise will enable you to avoid specification errors that could lead to premature failure, select cost-effective solutions that balance performance with budget constraints, and communicate design differences effectively when discussing butterfly valve requirements in your engineering or procurement role.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification