Air Torque Pneumatic Actuators Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

As part of our comprehensive Valve and Actuation Training programme, our Air Torque Pneumatic Actuators course delivers targeted education designed to understand actuator selection, sizing, and application across different valve types and process conditions. This specialised course focuses on Rack & Pinion, HD Compact, and Scotch Yoke technologies, providing participants with the expertise needed to match actuator performance to specific requirements and ensure reliable automation in critical applications.

To learn more about what to expect as part of this training course, view the table below. If you are interested in taking part in our next training session, fill out the nearby contact form.

Agenda

Pneumatic Actuator Fundamentals

Understanding how pneumatic actuators convert air pressure into rotary motion, basic operating principles, and the role of actuators in valve automation systems.

Actuator Technology Comparison

Analysis of Rack & Pinion, HD Compact, and Scotch Yoke designs, exploring their unique characteristics, performance advantages, and optimal application areas.

Sizing and Torque Calculations

Practical guidance on calculating torque requirements, matching actuator output to valve demands, and applying appropriate safety factors for different service conditions.

Operating Configuration Options

Examination of double-acting versus spring-return configurations, understanding fail-safe requirements, and selecting appropriate actuation modes for different applications.

Environmental and Process Considerations

Evaluation of temperature effects, media compatibility, duty cycle requirements, and environmental factors that influence actuator specification and performance.

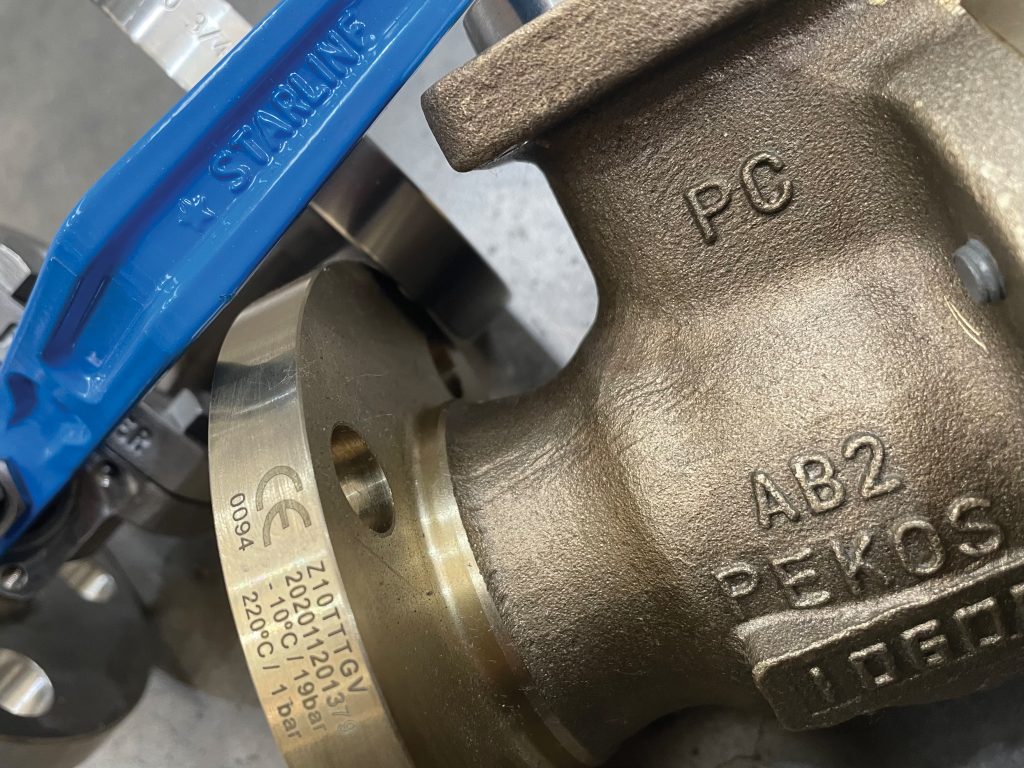

Industry Standards and Mounting

Understanding ISO 5211 mounting interfaces, international specifications, and ensuring compatibility between actuators and valve mounting systems.

Maintenance and Troubleshooting

Recognition of common operational issues, preventative maintenance practices, and strategies to extend actuator service life and reliability.

Practical Application and Selection

Case studies demonstrating real-world actuator selection decisions, cost versus performance trade-offs, and guidance for advising on optimal solutions.

Course Outcomes

By the end of the course, participants will confidently calculate actuator torque requirements and select appropriate technologies for different valve types, understand the critical differences between actuator configurations and their impact on system reliability, and evaluate environmental factors that affect actuator performance. This expertise will enable you to prevent undersizing failures, specify cost-effective automation solutions that meet safety requirements, troubleshoot common actuator issues, and provide informed technical guidance that ensures optimal actuator selection and long-term reliability in your engineering or procurement role.

Absolutely. We offer tailored training options to suit your specific equipment, industry needs, or workforce skill levels. Speak to us about a bespoke session designed around your objectives.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification