Actuators Vs Valves Training

Hands-on training

Benefits

- Industry-led advice

- Practical expertise

- Open to new and existing customers

- Brilliant aftercare services

- Valve stock & manufacturing services also available

- Course overview

- Agenda

- FAQs

Course overview

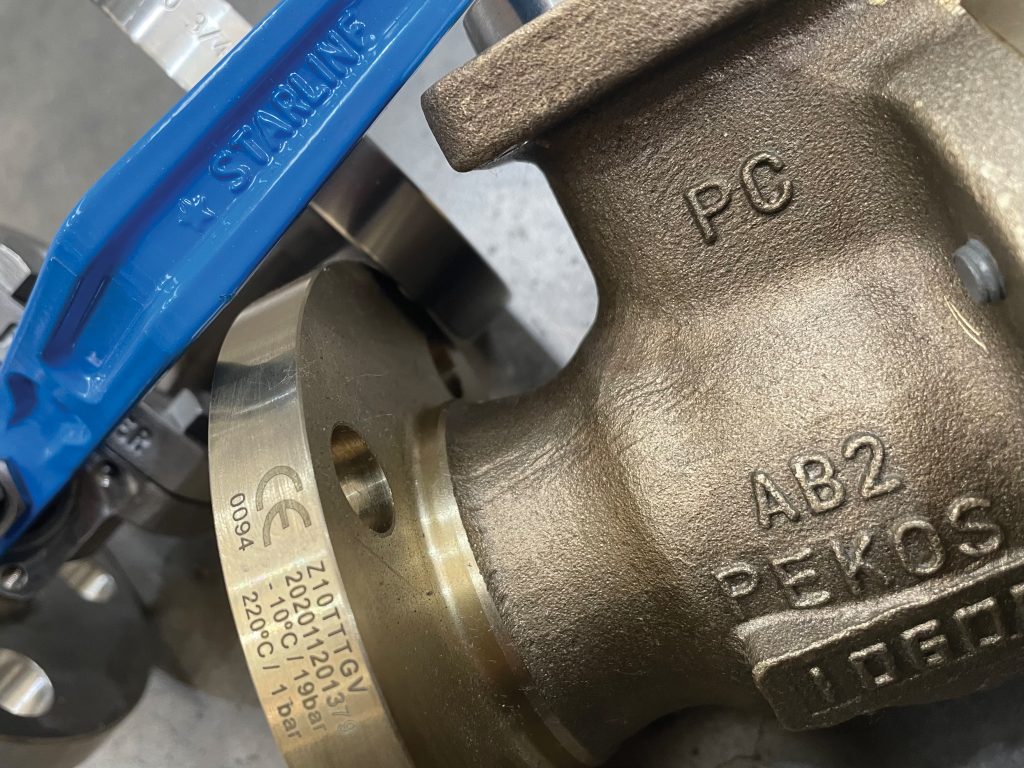

As part of our comprehensive Valve and Actuation Training programme, our Actuators vs Valves course delivers essential education designed to bridge the gap between valve requirements and actuator capabilities. This specialised course focuses on torque calculations, safety factors, and practical actuator selection, providing participants with the expertise needed to specify appropriate actuation solutions and avoid costly operational failures in critical applications.

To learn more about what to expect as part of this training course, view the table below. If you are interested in taking part in our next training session, fill out the nearby contact form.

Agenda

Manual Operation Fundamentals

Understanding torque principles, human force limitations, and the transition from lever operation to gearbox requirements based on API 6D standards.

Gearbox Technology and Applications

Exploration of reduction gearing principles, sizing criteria, and practical limitations including handwheel diameter restrictions and output torque calculations.

Actuator Types and Characteristics

Analysis of double acting versus spring return actuators, torque curves, and the relationship between actuator output and valve requirements throughout the operating cycle.

Torque Matching and Safety Factors

Understanding valve torque characteristics, momentum effects, and appropriate safety factors for different service conditions including liquid, gaseous, and high-temperature applications.

Sizing Challenges and Problem Solving

Examination of common actuator sizing issues, air supply considerations, and troubleshooting techniques for problematic applications.

Maximum Allowable Stem Torque (MAST)

Understanding stem material limitations, when specify upgraded stems, and the relationship between actuator size and valve structural integrity.

Special Applications

Analysis of Emergency Shutdown Valves (ESDs), positioner effects, and mounting standard requirements per BS EN ISO 5211:2023.

By the end of the course, participants will confidently calculate torque requirements and select appropriate actuators, understand when gearboxes are necessary versus lever operation, and apply correct safety factors for different service conditions. This expertise will enable you to prevent actuator undersizing failures, avoid costly field problems, and specify reliable actuation solutions that balance performance requirements with practical constraints in your engineering or procurement role.

Additional valve services

Project Supply

Pipe & Skid Solutions

Valve Modification