In-House Valve Testing

Certified hydrostatic, pneumatic, functional, cryogenic, hydrogen, and high-pressure testing performed in our UK facility with full documentation and compliance.

ACV provides comprehensive in-house valve testing to ensure every product meets the performance, safety, and compliance requirements of your project. Our UK testing facilities are equipped for hydrostatic, pneumatic, functional, cryogenic, and high-pressure testing, allowing us to validate valves from our extensive stock range or customer-supplied equipment with complete accuracy and traceability.

Our experienced engineering team performs all tests to the latest international standards, producing fully documented certification packages, test records, and quality reports for guaranteed compliance. With immediate access to spares, gaskets, fittings, and stocked valves, we can carry out repairs, adjustments, and retests without delay – reducing downtime and supporting urgent project timelines.

With over 25 years of industry expertise, we help you gain confidence in valve performance, eliminate the risk of field failures, and ensure every unit leaves our facility fully tested, compliant, and ready for installation.

Benefits we provide

- Comprehensive in-house testing capabilities for fast turnaround and guaranteed compliance

- Hydrostatic, pneumatic, functional, and fugitive emissions testing for all valve types

- Fully certified, traceable test equipment calibrated to international standards

- Confidence that every valve supplied performs exactly as your application demands

Support we offer

- Pressure testing to project specifications and international test protocols

- Seat leakage verification, shell testing, and functional cycling

- Witness testing, third-party inspection, and customer-specific documentation packs

- FAT support for automated valves, including actuator function and control checks

- Test certificates issued in your preferred format for seamless project submission

- Support for large volume, multi-line, and critical-service testing requirements

Industries we work with

- Oil and gas

- Hydrogen

- Carbon capture

- Power generation

- Energy storage

- General process

- Water

- Steel

- Chemical

- Petrochemical

Valve Testing Team

Richard Clapp

Technical Valve Services Director

Sudhir Jaycee

Workshop Manager

Jamie Bartlett

Workshop Supervisor

Andy Lewin

Fitting and Testing Technical Lead

Case study

- Comprehensive API 598 hydrostatic and pneumatic testing

- Fugitive emissions testing using helium to ISO 15848-2

- Accurate identification of leakage source (stem area)

- Full witness testing conducted and documented

- Detailed test reporting supplied to the customer

- Independent third-party verification of valve performance

See how we do it

Our Process

Our valve testing process ensures every valve we handle is verified for performance, reliability, and compliance with project and industry standards. Using controlled procedures, calibrated equipment, and full traceability, each stage confirms that the valve is ready for safe and dependable service.

Test Requirement Review

We assess the valve type, service conditions, customer specifications, and applicable standards. This defines the required test methods, pressures, durations, and acceptance criteria before testing begins.

Valve Preparation

Valves are visually inspected, cleaned, and prepared for test. All identification, documentation, and certification details are checked to ensure full traceability throughout the process.

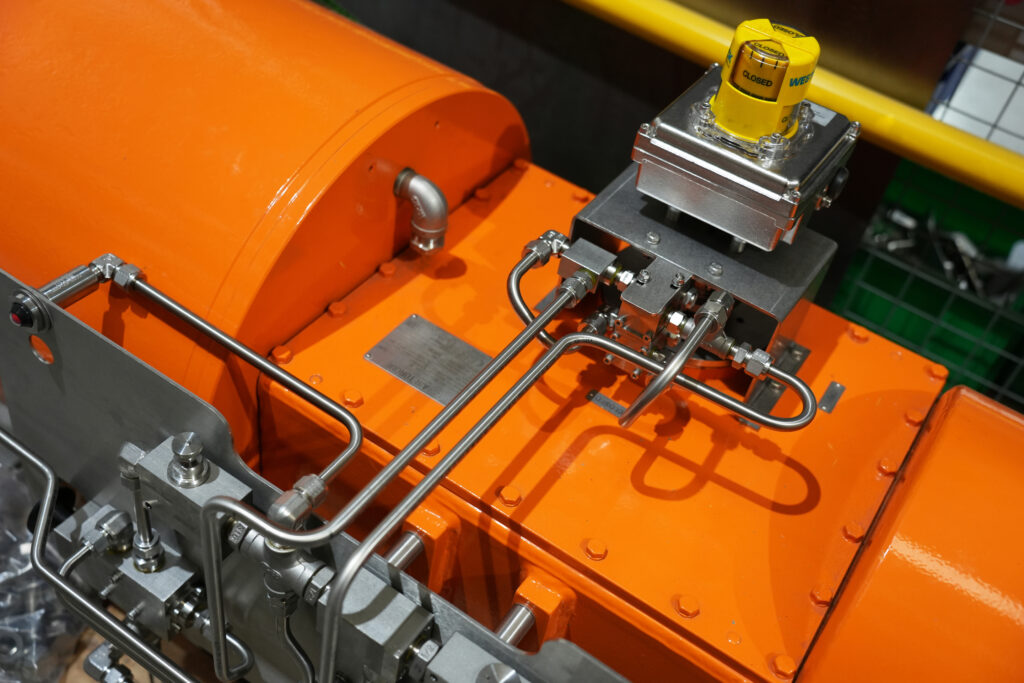

Fixture Setup

The valve is mounted to the appropriate test rig using calibrated fittings, flanges, or adapters. Clamping and sealing arrangements are confirmed to ensure a secure, compliant testing environment.

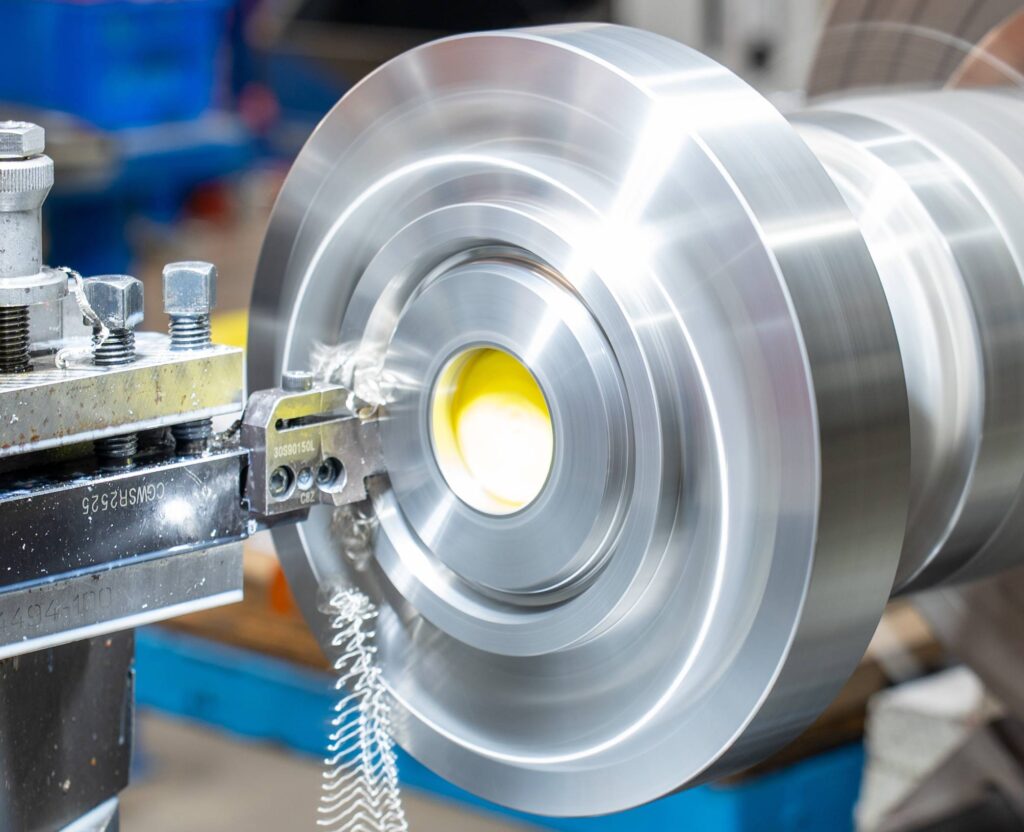

Hydrostatic Testing

Valves undergo body and seat hydrostatic tests using controlled pressure increases and monitored hold periods. This verifies structural integrity, pressure retention, and leak-tightness under specified conditions.

Pneumatic Testing

Where required, valves are tested with air or inert gas at low or high pressures. Sensitive leak detection methods confirm tight shut-off and verify functional performance.

Functional Testing

Operational checks are performed to ensure smooth actuation, correct travel, torque requirements, and consistent opening/closing characteristics. Manual, pneumatic, or electric operation is validated as applicable.

Specialised Testing

Application-specific tests, such as vacuum testing, high-pressure gas testing, cryogenic performance checks, or seat leakage verification, are conducted according to customer requirements and relevant standards.

Final Inspection

Post-test inspections confirm valve condition, cleanliness, marking, and specification compliance. All results are verified against test criteria and project documentation.

Certification & Documentation

A complete test record is produced, including pressure charts, inspection reports, calibration certificates, and any customer-required documentation. Witnessed testing and third-party inspection can be arranged when specified.

Packing & Dispatch

Following test approval, valves are drained, dried, protected, and securely packed. All documentation is included to ensure seamless integration into project QA systems.

Valve testing services

Valve Automation

Valve Modification

TVS Valve Manufacturing

Project Supply

Resources

View all resourcesYes. We can provide high-pressure gas testing, helium leak testing and other specialist procedures for valves used in critical, high-integrity, or cryogenic applications. These tests are performed using dedicated equipment and documented to meet stringent industry and customer standards.