Comprehensive Valve Stock and Supply

Extensive UK and European valve stock supported by a global supply network, full certification, and expert guidance you can trust.

ACV provides fast, reliable access to one of the UK and Europe’s most comprehensive valve stockholdings, supported by a trusted global supply network. Our extensive inventory enables same-day dispatch for urgent requirements, shutdowns, and critical maintenance, while maintaining full material traceability and compliance with internationally recognised standards.

Every enquiry is supported by experienced valve specialists who assess application, pressure, temperature, materials, and certification requirements to ensure the right valve is supplied first time. Whether supplying from stock, sourcing to your AVL, or supporting complex project schedules, we deliver certainty, speed, and technical assurance across every order.

Benefits we provide

- Premium European-manufactured options with full traceability for critical service

- Instant access to a market-leading valve stockholding ready for same-day dispatch

- Fast, reliable sourcing from our global supply network to match your AVL without delay

- Valves supplied to internationally recognised standards for guaranteed performance and compliance

Support we offer

- Specialist guidance to secure the right valve, first time

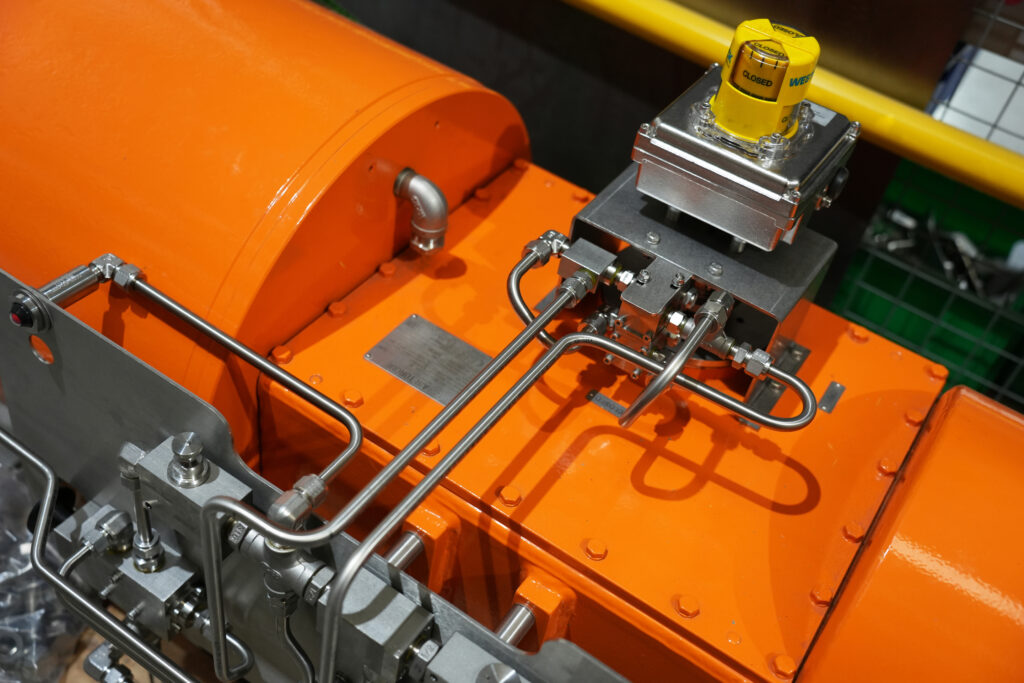

- Automation readiness checks, torque verification, and technical support

- Project-ready documentation, certification, and tailored format packs

- Inspection, testing, and witness testing to meet customer or project requirements

- Spare parts, upgrades, and long-term lifecycle supply continuity

- High-volume, multi-line, and complex project fulfilment with ease

Industries we work with

- Carbon capture

- Hydrogen

- Energy storage

- Oil and gas

- Power generation

- General process

- Water

- Steel

- Waste heat recovery

- Combustion

Valve Stock and Supply Team

Gary Plant

Group Sales Director

Stefan Stringer

Commercial Director

Stuart Armstrong

UK Sales Manager

Craig Clements

Area Sales Manager

Harry Flint

Operations Director

Drew Prescott

Export Sales Director

Mark Conway

Sales Office Manager

Wesley Cooper

Technical Sales & Applications Engineer

Peter Knight

Sales Engineer

Luke Beasley

Sales Engineer

Callum Rousseau

Sales Engineer

Michael Conway

Sales Engineer

Dan Robbins

Sales Engineer

Case study

- Supplied directly from in-stock inventory

- Fully certified and quality-checked prior to shipment

- Same-day turnaround and dispatch

- 1 × 2" ANSI 150RF stainless-steel 3-way valve

- 2 × 1" Class 900 NPT Starline carbon-steel valves

- Reviewed the specification and matched it with existing stock

See how we do it

Our Process

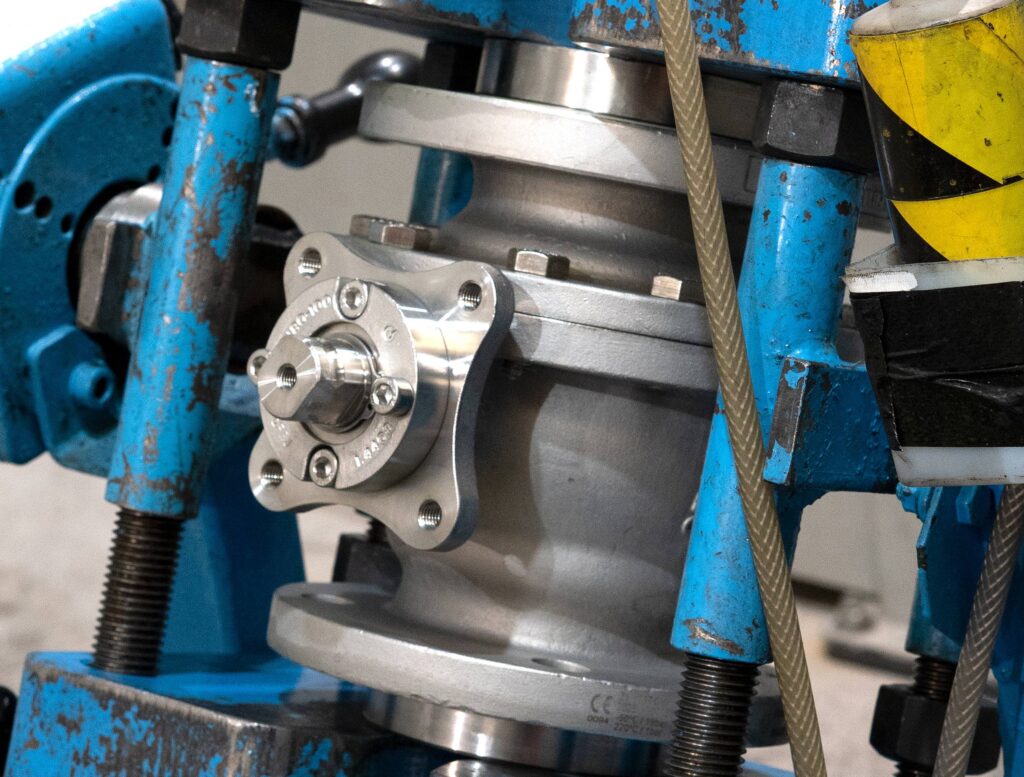

Our valve stock and supply process ensures fast, reliable delivery of high-quality valves through our extensive inventory and global sourcing network. Every order is managed with precision, traceability, and rigorous quality control to support maintenance, operations, and complex project requirements.

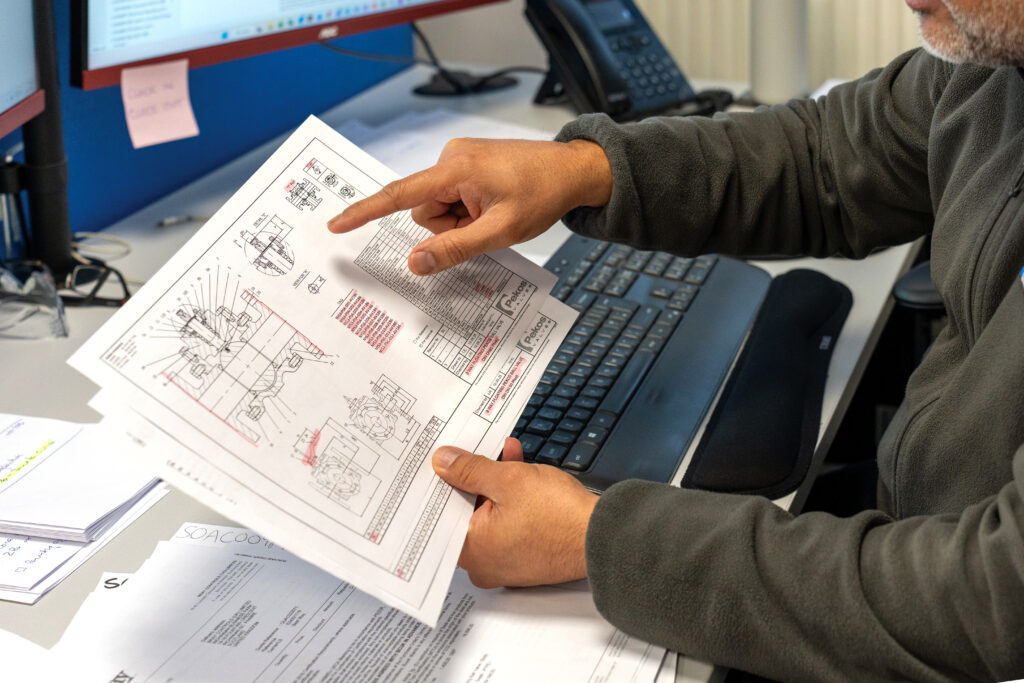

Enquiry Review & Specification Check

We assess the application, service conditions, materials, pressure class, and compliance requirements. For specialist or technically challenging enquiries, our engineering team completes a detailed technical review to confirm suitability and define the correct product configuration.

Stock Assessment & Global Sourcing

Our teams review live inventory across UK and European warehouses to identify the most efficient supply route. Where required, we evaluate whether the enquiry can be fulfilled through engineered adaptations, in-house manufacturing capability, or controlled modification of existing stock. We can also source the product through our approved global supply network, aligned to AVL and specification requirements

Quotation

A clear, detailed quotation is provided, including technical specification, materials, documentation, pricing, and delivery. We discuss alternative options or clarifications before order placement to ensure full alignment

Order Processing

Once the order is received, specifications, standards, and documentation requirements are verified. Order acknowledgements and any supplier sub-orders are issued to align availability, sourcing, and timelines.

Quality Control & Inspection

Valves are inspected against drawings, order details, and certification requirements. Traceability, markings, materials, and documentation are verified. Any additional tests (such as hydrostatic, pneumatic, or functional) are carried out as specified.

Documentation Preparation

All required documents—including certificates, test reports, data sheets, and project-specific packs—are compiled in the correct format. Full documentation sets are produced for project-critical orders.

Packing

Valves are cleaned, protected, and securely packed in cartons, pallets, or ISPM15 export cases. All packing includes correct labelling, identification, and documentation for seamless receipt.

Dispatch & Logistics

Orders are dispatched via courier, haulier, or freight forwarder, or prepared for customer collection. All shipments include the required documentation to support quality, traceability, and project integration.

Stock & supply services

Valve Automation

Valve Modification

Valve Testing

Project Supply

Resources

View all resourcesYes. Alongside our extensive stock, we work with our core European manufacturing partners to source or produce specialist valves that are not held on the shelf. This includes custom materials, special trims, severe-service designs, and project-specific configurations, ensuring complete coverage for all procurement needs.