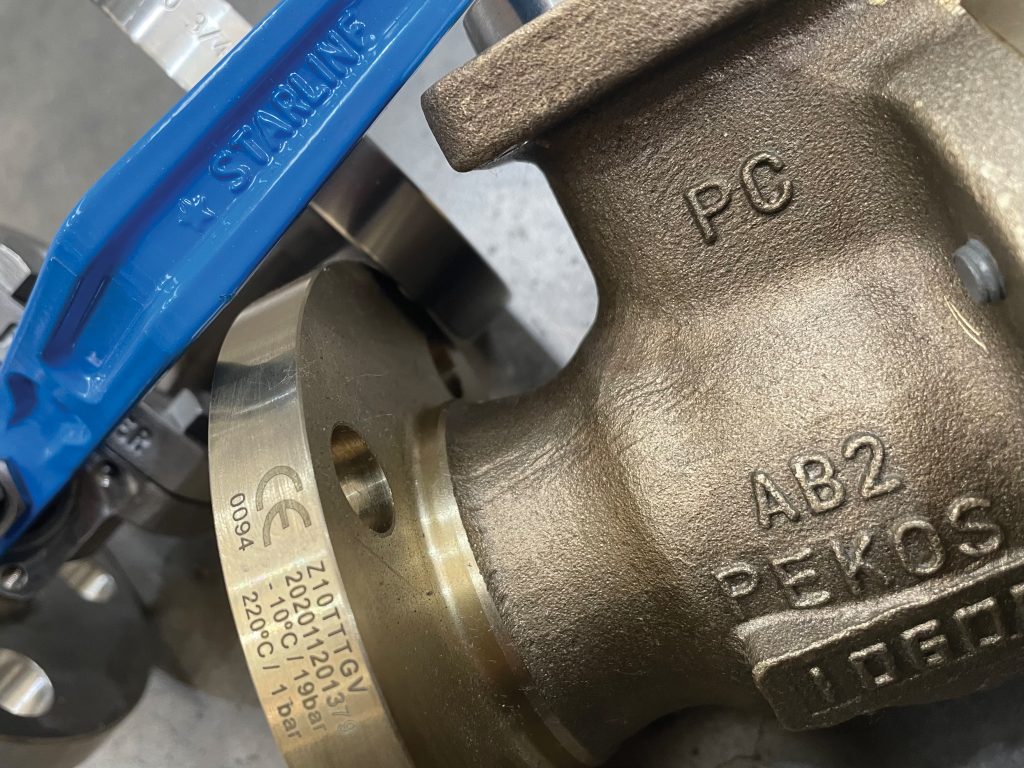

In-House Valve Modification

Fast, fully certified valve modifications including trim changes, material upgrades, welding, end connections, and project-specific configurations.

ACV provides fast, reliable, in-house valve modification services backed by one of Europe’s most comprehensive valve stock ranges and a dedicated inventory of critical spares. Our engineering team carries out a wide range of modifications—including trim changes, material upgrades, welding, overlays, extended stems, end-connection changes, automation preparation, and special testing—ensuring every valve is built exactly to your project specification.

All work is completed in our UK facilities under strict quality control, with full certification, traceability, and documentation. Whether you need urgent replacements, specialist materials, or bespoke configurations, we can modify from stocked valves or source additional components through our global supply network to keep your project moving without delay.

With over 25 years of engineering experience, we help you avoid long factory lead times, meet unique service requirements, and receive valves that are correctly configured, fully tested, and ready for immediate installation.

Benefits we provide

- Fast-track valve modifications carried out in-house for rapid turnaround

- Enhanced performance solutions including trim changes, material upgrades, and configuration adjustments

- European-sourced components with full traceability for critical applications

- Modified valves supplied to recognised international standards for assured reliability

Support we offer

- Technical evaluation to identify the optimal modification for your application

- Stem extensions, locking devices, gearbox changes, mounting kits, and custom actuation interfaces

- High-temperature, cryogenic, and severe-service preparation

- Inspection, testing, and witness testing following all modifications

- Project documentation, certification updates, and customer-specific formats

- Spare parts sourcing and long-term lifecycle support for modified valves

Industries we work with

- Oil and gas

- Hydrogen

- Carbon capture

- Power generation

- Energy storage

- General process

- Water

- Steel

- Chemical

- Petrochemical

Valve Modification Team

Richard Clapp

Technical Valve Services Director

Sudhir Jaycee

Workshop Manager

Jamie Bartlett

Workshop Supervisor

Dave Papworth

Design Engineer

Anees Diwan

Junior Design Engineer

Robert Marshall

Machinist

Justin Cornwall

Machinist

Lukasz Popielnicki

Machinist

Daniel Stothard

Valve & Actuation Fitting & Testing

Jacob Baines

Apprentice Fitter

Case study

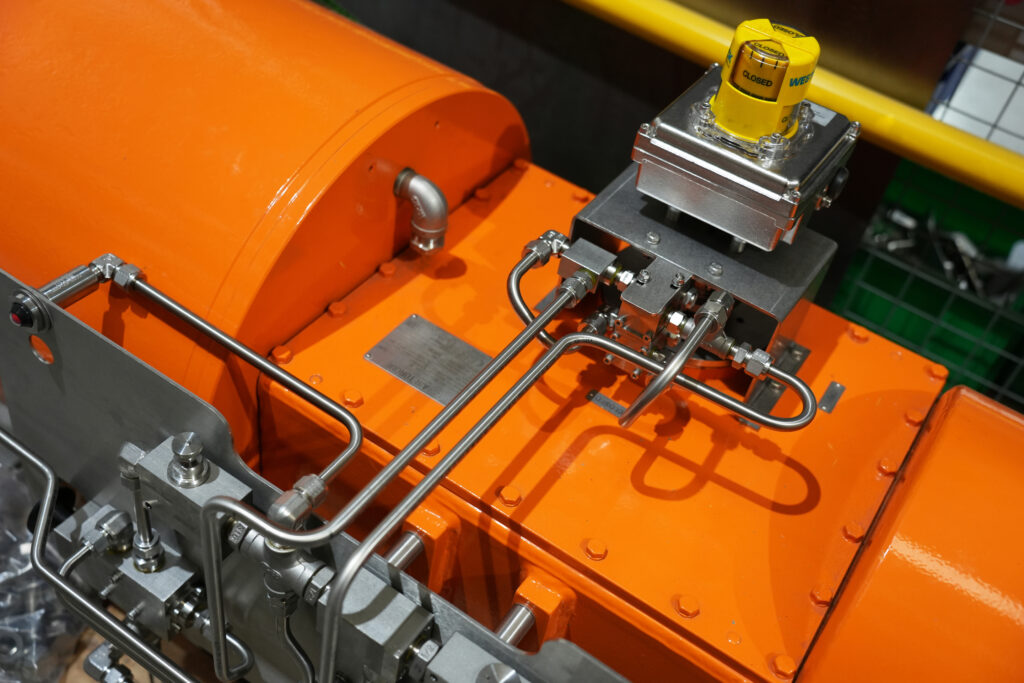

- Four 24” Class 600 Perar trunnion-mounted ball valves pulled from stock

- Valves machined from general-ended to raised-face configuration

- Installation optimised at a 90° orientation to maintain gearbox height requirements

- Integration of Galli & Cassina plug valves on vent and drain ports

- V8 injection valves installed on stem and seat sealant points

- All components positioned at precise operational angles

- Valves painted to client specification for final delivery

- Project delivered on time, meeting all performance and site requirements

See how we do it

Our Process

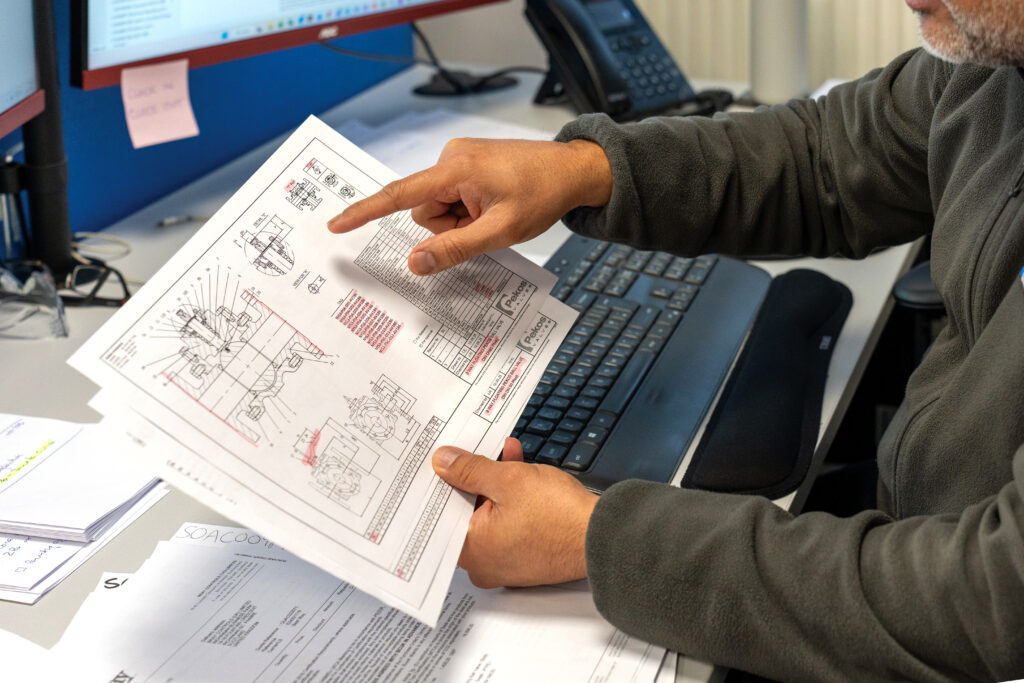

Our valve modification process delivers engineered solutions that adapt existing valves to specific project or operational requirements. Each stage is controlled, traceable, and carried out by skilled technicians to ensure performance, compliance, and long-term reliability.

Application & Requirement Review

We assess the valve’s intended service, media, temperature, pressure class, materials, and any project constraints. This defines the modification scope and ensures complete alignment with customer and industry requirements.

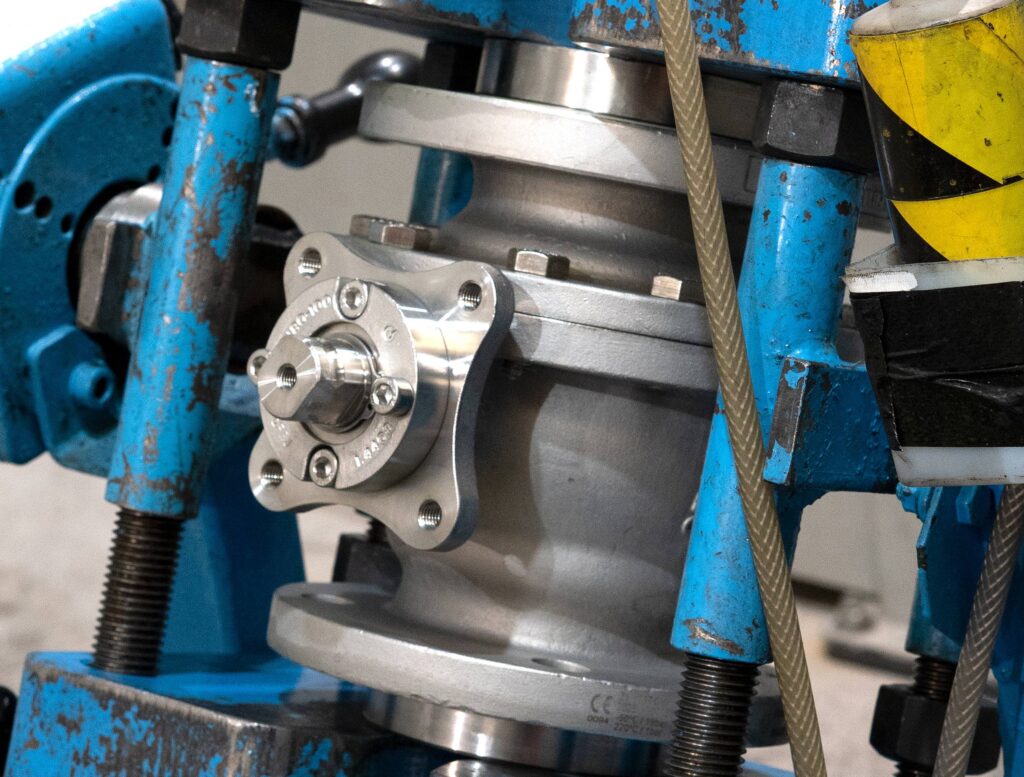

Valve Inspection & Preparation

Incoming valves are cleaned, visually inspected, and fully verified against documentation. Dimensional checks, material traceability, and component condition assessments ensure suitability for modification.

Machining & Adaptation

Precision CNC machining is carried out to produce components such as adapter plates, brackets, stem extensions, drilled/tapped features, and interface parts. All machining is performed to tight tolerances to ensure seamless integration.

Trim Adjustments & Component Changes

Internal components, such as seats, seals, stems, or balls/plugs, are replaced or upgraded where required. All replacements follow controlled work instructions to maintain performance and compatibility with service conditions.

Cleaning & Specialist Processes

Where applicable, valves undergo controlled procedures such as degreasing, oxygen cleaning, or high-purity preparation to meet project or industry-specific requirements.

Assembly & Build

Valves are reassembled to the required configuration using new or modified components. All assemblies are built following approved procedures to ensure functional reliability and traceability.

Testing & Validation

Modified valves are hydrostatically, pneumatically, and functionally tested in accordance with applicable standards. Testing verifies that all changes meet the required performance, sealing, and operational criteria.

Coating & Finishing

External surfaces are cleaned and recoated as required to ensure corrosion protection and suitability for the intended environment.

Final Inspection

Every valve undergoes a final inspection to confirm dimensional accuracy, operational performance, and compliance with specifications. Documentation, serialisation, and traceability records are updated accordingly.

Packing & Dispatch

Valves are securely packed, labelled, and supplied with all supporting test records, certificates, and documentation to ensure seamless integration into project systems.

Valve modification services

Valve Stock & Supply

Valve Automation

Valve Testing

Project Supply

Resources

View all resourcesYes. We can provide high-pressure gas testing, helium leak testing and other specialist procedures for valves used in critical, high-integrity, or cryogenic applications. These tests are performed using dedicated equipment and documented to meet stringent industry and customer standards.