In-House Valve Automation

Engineered pneumatic, electric and hydraulic automation packages built, configured, and fully tested in-house with complete certification and technical assurance.

ACV delivers fully engineered valve automation solutions built in-house by our dedicated automation specialists. Combining deep technical expertise with one of Europe’s most comprehensive stocks of valves and actuators, we provide complete pneumatic, electric, and hydraulic assemblies tailored to your exact torque, control, and certification requirements.

Every package is assembled, configured, and tested in our UK automation facility, ensuring accurate sizing, seamless integration, and long-term reliability. From on/off assemblies and failsafe systems to complex control solutions with positioners, switchboxes, and instrumentation, each build follows strict quality procedures and full traceability.

Supported by our extensive stockholding and global supply network, we can deliver fast-track automated valve packages for urgent replacements, shutdowns, and project requirements. With more than 25 years of experience, we help you avoid compatibility issues, reduce installation time, and gain confidence that every automated valve arrives fully certified, correctly built, and ready to perform from day one.

Benefits we provide

- Fully engineered automation packages built in-house for fast, reliable delivery

- Pneumatic, electric, and hydraulic actuation solutions tailored to your application

- Direct access to premium European actuator brands with full traceability

- Complete valve-and-actuator assemblies supplied to international standards for assured performance

Support we offer

- Torque calculations, sizing, and actuator selection for any valve type

- Custom mounting kits, bracketry, and coupling solutions manufactured in-house

- Control panel design, switchboxes, positioners, and full accessory integration

- Factory testing, functional testing, and witness testing available on request

- Project documentation, certification packs, and customer-specific formats

- Ongoing service, spare parts, and lifecycle support to keep assets performing

Industries we work with

- Oil and gas

- Hydrogen

- Carbon capture

- Power generation

- Energy storage

- General process

- Water

- Steel

- Chemical

- Petrochemical

Valve Automation Team

Graham Adams

Technical Manager Automation

Noel Corbally

Automation Sales Engineer

Lakshay Giri

Production Engineer

Kyle Adams

Technical Engieer

Sean Bailey

Actuation Technical Lead

William Cavill

Trainee Actuation Fitter & Tester

See how we do it

Our Process

Our valve automation process delivers fully-engineered, automated valve packages built for reliability, precision, and seamless integration into customer systems. Every assembly is built under controlled procedures, ensuring full traceability, consistent quality, and dependable performance across all applications.

Application & Requirement Review

We assess media, temperature, pressure class, torque requirements, fail position, control philosophy, and site conditions. This defines the correct actuator type, sizing, mounting configuration, and accessory requirements.

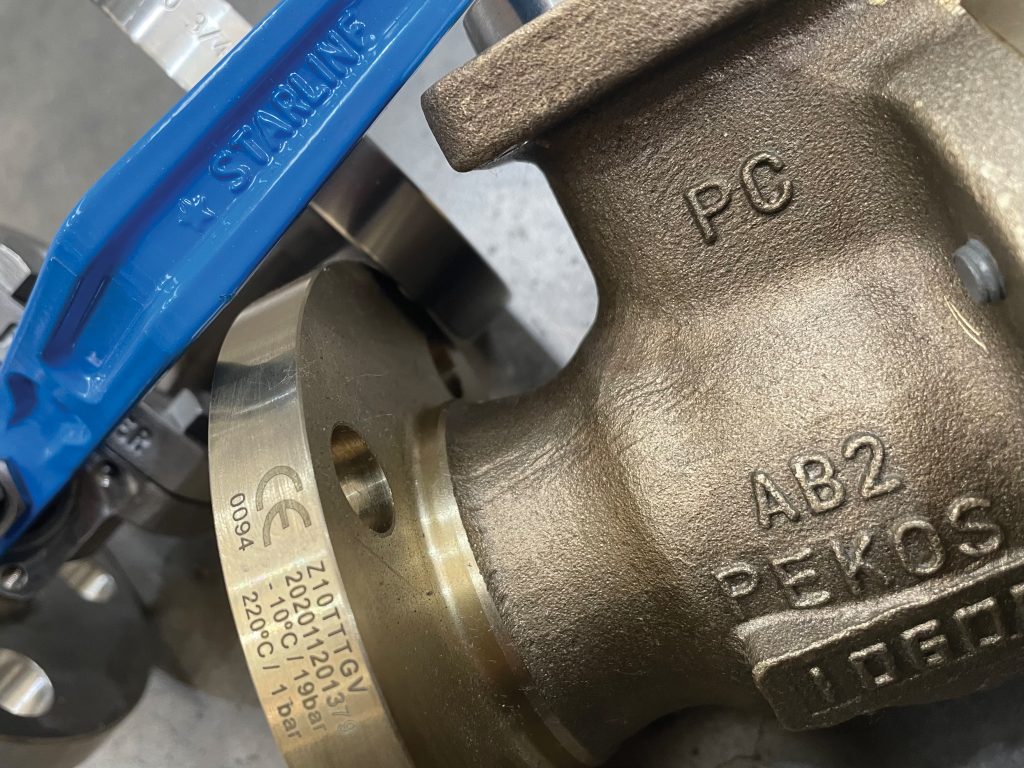

Valve & Actuator Preparation

Valves and actuators undergo initial inspection to confirm specification, compatibility, documentation, and traceability. Threads, flanges, and interfaces are checked to ensure readiness for automation.

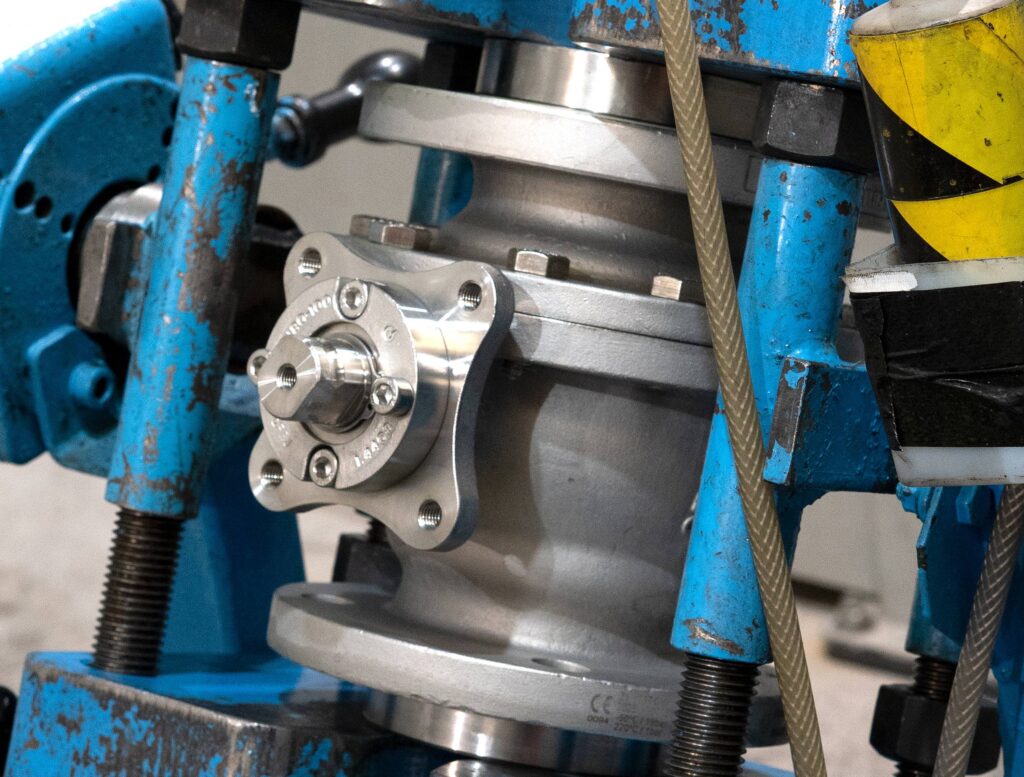

Mounting Kit Engineering

A precision-engineered mounting kit, bracket, drive bush, couplings, or adapter plate is added to ensure perfect alignment between valve and actuator. This guarantees smooth operation and long-term mechanical integrity.

Actuator Sizing & Configuration

Actuators are sized using verified torque data and safety margins. Pneumatic, electric, or hydraulic actuators are configured to meet required fail-safe position, operating speed, and control method.

Assembly & Build

The valve, actuator, and mounting kit are assembled under controlled conditions. All mechanical interfaces are aligned and torqued correctly, ensuring stable, repeatable operation without stress or distortion.

Accessories & Control Integration

Positioners, limit switches, solenoids, filter regulators, and other accessories are installed and calibrated. Wiring, tubing, and connections follow approved layouts to ensure safe and reliable control.

Functional Testing

Each automated package undergoes full functional testing, including stroke verification, torque checks, open/close timing, signal calibration, and fail-safe testing. Optional customer-witnessed FAT confirms performance and compliance.

Final Inspection

A complete inspection verifies mechanical integrity, correct control response, alignment, tagging, and documentation accuracy. All serial numbers, settings, and calibration data are recorded for traceability.

Packing & Dispatch

Automated packages are securely packed and labelled to protect critical components and instrumentation. All documentation, including test reports, wiring diagrams, torque charts, and certificates, is supplied for seamless site installation.

Automation services

Valve Stock & Supply

Valve Modification

Valve Testing

Project Supply

We work with established global manufacturers including Air Torque for pneumatic actuation, Bernard for electric actuation, AUMA for specialist applications, and additional partners covering electro-hydraulic and bespoke systems.

Alongside our core supply base, we can source alternative actuator brands and configurations to meet your project, environmental, or customer-specific requirements, ensuring you receive the most suitable and reliable automation package for your application.