UK Valve Manufacturing

Bespoke valves produced in-house with specialist materials, engineering expertise and fast-track solutions for complex applications.

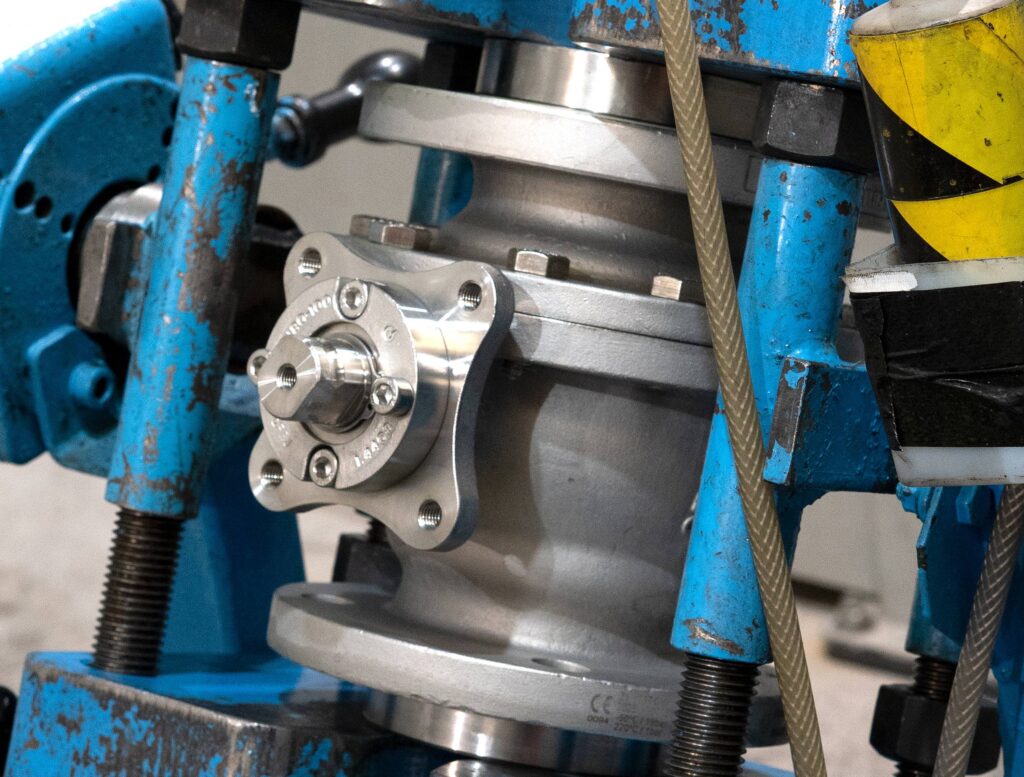

Technical Valve Services (TVS), part of the ACV Group, provides precision-engineered valve manufacturing and bespoke assembly solutions designed for demanding service conditions. Operating from our UK facility, our engineering team manufactures and builds valves using high-integrity materials, specialist trims, and fully traceable components sourced from our extensive stockholding and trusted global supply network.

Whether you require custom-engineered valves, exotic material builds, replacement internals, overlayed components, or project-specific assemblies, every product is manufactured under strict quality control and supplied with complete certification. Our facility is equipped to manage specialist welding, machining, seat and stem upgrades, cryogenic, and high-temperature configurations, as well as full assembly and testing.

With more than 25 years of manufacturing and engineering expertise, we help you overcome long factory lead times, resolve obsolescence challenges, and secure high-performance, fully certified valves tailored to your exact operational requirements.

Benefits we provide

- Bespoke valve manufacturing for severe-service valves, delivered at speed

- Fully-traceable European materials and components for critical-service assurance

- Fast-track production to support shutdowns, obsolescence replacement, and AVL requirements

- Precision-built valves supplied to recognised international quality and performance standards

Support we offer

- Technical guidance on material selection, trims, and service-specific configurations

- In-house machining, fabrication, assembly, and specialist build capability

- High-temperature, cryogenic, and severe-service preparation

- Inspection, pressure testing, functional testing, and witness testing

- Project documentation, certification packs, and customer-specific formats

- Spare parts sourcing, repeat-build consistency, and lifecycle support for long-term projects

Industries we work with

- Oil and gas

- Hydrogen

- Carbon capture

- Power generation

- Energy storage

- General process

- Water

- Steel

- Chemical

- Petrochemical

TVS Valve Manufacturing Team

Richard Clapp

Technical Valve Services Director

Sudhir Jaycee

Workshop Manager

Jamie Bartlett

Workshop Supervisor

Dave Papworth

Design Engineer

Anees Diwan

Junior Design Engineer

Robert Marshall

Machinist

Justin Cornwall

Machinist

Lukasz Popielnicki

Machinist

See how we do it

Our Process

Our TVS manufacturing process delivers precision-engineered valves produced under strict quality controls, ensuring reliability, consistency, and full traceability at every stage. From material preparation to final inspection, each step is designed to meet exacting project and industry standards.

Project Assessment & Specification

We review the customer’s requirements, including application details, materials, service conditions, and delivery expectations. This ensures a complete understanding of the valve design before manufacturing begins.

Material & Component Preparation

All raw materials and components are sourced from approved suppliers and undergo initial inspection. Each forging or casting is verified for compliance and traceability before entering production.

CNC Machining

Using advanced CNC equipment, bodies, end connections, stems, balls, and internal components are precision-machined to exact tolerances. Each part is produced to deliver uniform, repeatable performance across the full manufacturing batch.

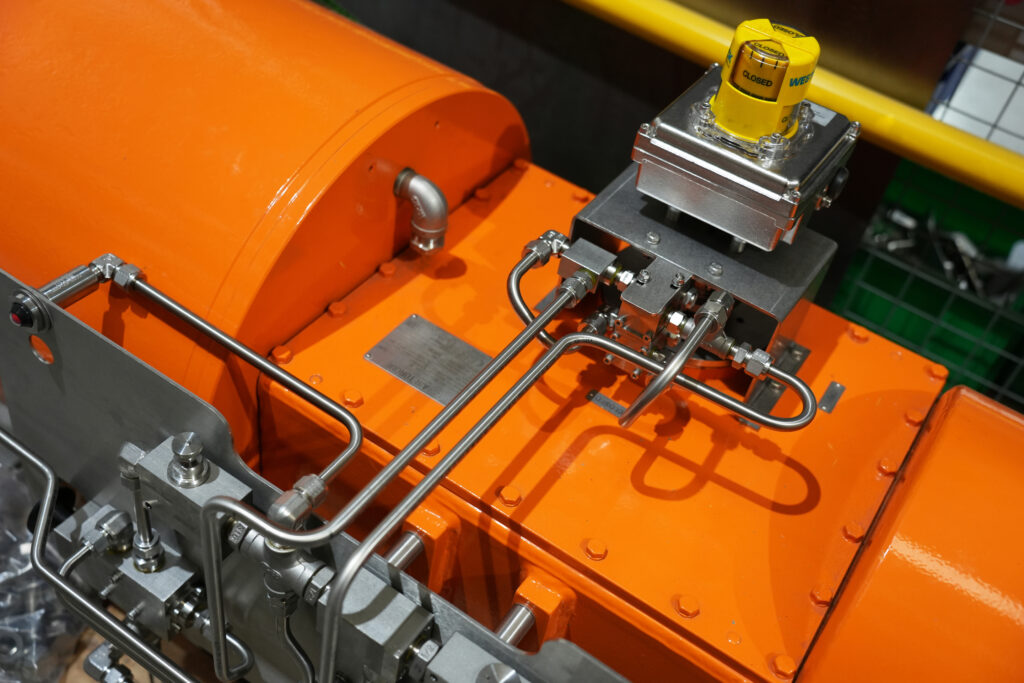

Assembly

Manufactured components are assembled by trained technicians following controlled work instructions. Seats, seals, stems, and functional elements are fitted with precision to ensure smooth, reliable valve operation.

Testing & Validation

Every valve undergoes hydrostatic, pneumatic, and functional testing to confirm integrity, performance, and compliance with manufacturing and customer requirements. Witnessed testing is available upon request.

Coating & Finishing

Valves are cleaned, prepared, and coated to deliver long-term corrosion protection and environmental durability. Final finishes are applied in line with customer or project specifications.

Final Inspection

Each completed valve is inspected against drawings, specifications, and quality standards. Dimensional checks, visual inspections, and documentation reviews ensure full conformity and complete batch traceability.

Packing & Dispatch

Valves are securely packed, labelled, and supplied with all supporting documentation and certificates. Export-ready packaging options, including ISPM15 wooden cases, ensure safe transport to global destinations.

Valve manufacturing services

Valve Modification

Valve Testing

Valve Automation

Pipe & Skid Solutions

Resources

View all resourcesYes. Every valve manufactured by TVS includes complete documentation, including material certificates, welding records, NDE results, pressure and functional test certificates, drawings, and project-specific documentation requirements. Full Manufacturing Record Books (MRBs) can be supplied in your required format, ensuring complete traceability and compliance for audits, inspections, and long-term asset management.