In-House Starline Manufacturing

Factory-approved and licensed UK manufacturing delivering fully traceable, precision-built Starline ball valves with fast-track availability.

ACV provides dedicated access to Starline’s specialist forged steel valve manufacturing, delivering high-integrity ball valves engineered for performance, durability, and complete material traceability. Manufactured in Europe using fully certified materials and proven forging processes, every Starline valve is built to withstand demanding service conditions and maintain long-term sealing integrity.

Through our in-house Starline manufacturing support and close partnership with the factory, we offer fast-track build schedules, custom trim options, bespoke configurations, and full documentation packages tailored to your project requirements. Whether you need specific materials, cryogenic preparation, extended stems, specialist seats, or project-specific upgrades, every valve is assembled, tested, and certified to the highest standards.

With extensive UK and European stockholding backed by a global supply network, we help you reduce lead times, secure consistent availability, and receive Starline valves that are correctly manufactured, fully compliant, and ready for immediate installation.

Benefits we provide

- In-house manufacturing of Starline-based valve solutions for rapid delivery

- Bespoke builds, trims, and configurations using fully traceable European materials

- Fast-track production for shutdowns, AVL compliance, and urgent project needs

- Valves assembled, configured, and tested to globally recognised performance standards

Support we offer

- Technical guidance to specify the right Starline configuration for your application

- Material upgrades, trim changes, and service-specific preparation undertaken on site

- In-house machining, assembly, automation, and custom build capability

- Full inspection, pressure testing, and witness testing for project assurance

- Comprehensive certification packs and project documentation in customer-preferred formats

- Spare parts, long-term maintenance support, and repeat-build consistency for large projects

Industries we work with

- Oil and gas

- Hydrogen

- Carbon capture

- Power generation

- Energy storage

- Petrochemical

- General process

- Water

- Steel

- Chemical

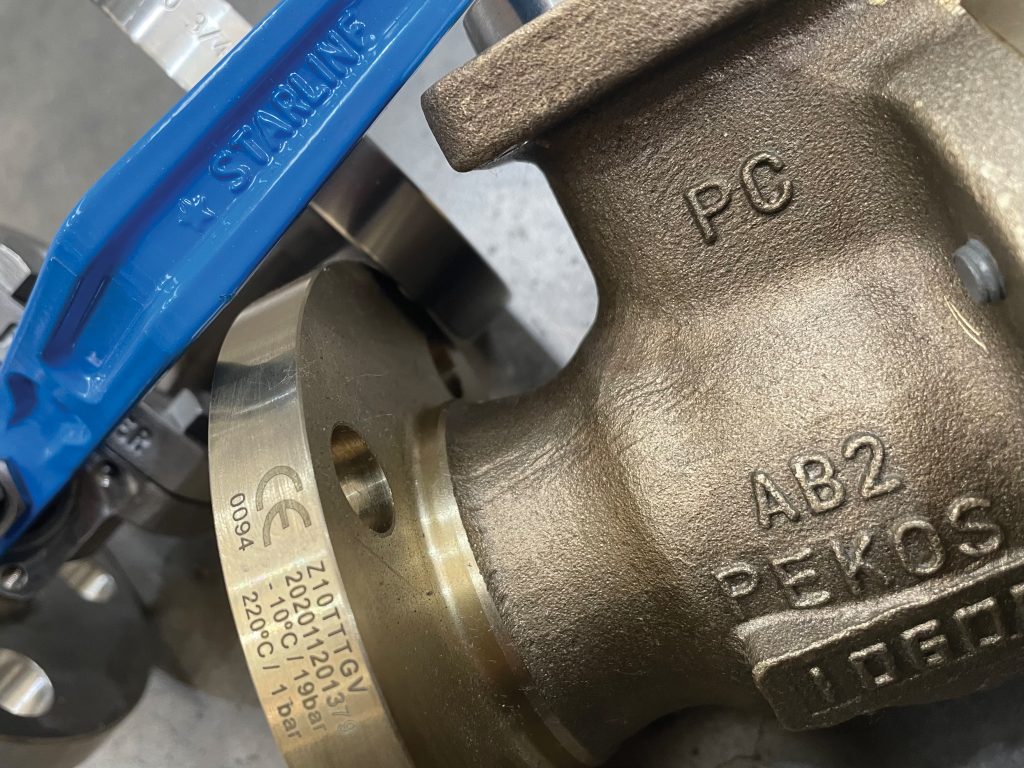

Case study

- Raw materials sourced and components manufactured in-house

- Lead time reduced by more than 50% through fast-track production

- Aluminium bronze valves built to required specification

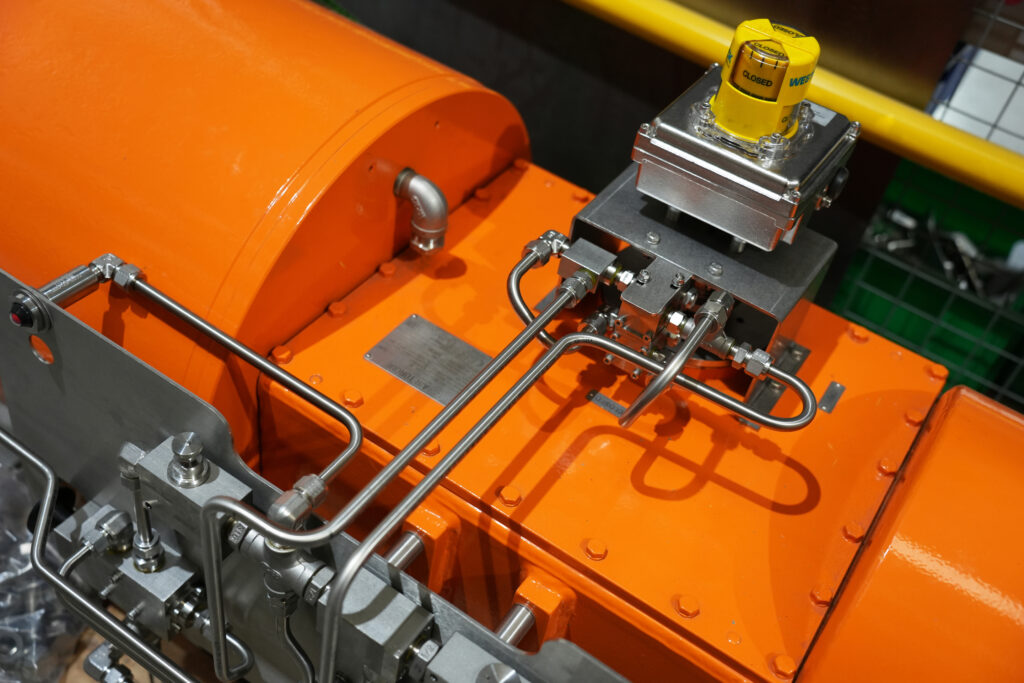

- Valves actuated with Air Torque stainless steel actuators (fail-close)

- Full component sourcing for manufacturing and automation

- Finished package coated for offshore environmental protection

- Delivered to specification within the accelerated timeline

See how we do it

Our Process

Our Starline manufacturing process ensures every ball valve is produced with precision, consistency, and full material traceability. From raw material selection to final inspection, each stage is tightly controlled to deliver reliable performance for critical industrial applications.

Material Sourcing & Preparation

Starline source fully European-forged materials under strict traceability controls. Each forging is verified for compliance before entering production, ensuring consistency and integrity from the very first stage.

CNC Machining

Forgings are precision-machined using advanced CNC technology to achieve exact tolerances and critical dimensions. Every component is produced to deliver repeatable quality and high-performance functionality across all valve designs.

CNC Machining

Using advanced CNC equipment, bodies, end connections, stems, balls, and internal components are precision-machined to exact tolerances. Each part is produced to deliver uniform, repeatable performance across the full manufacturing batch.

Assembly

Machined components are assembled by skilled technicians following controlled procedures. Seats, seals, stems, and internal components are fitted with exacting care to deliver smooth, reliable operation.

Testing

Each valve undergoes hydrostatic, pneumatic, and functional testing to verify tight shut-off, integrity, and performance. Test procedures follow proven Starline methodologies to ensure every unit meets the required operational standards.

Surface Treatment & Finishing

External surfaces receive protective coating and finishing processes designed to deliver longevity, corrosion resistance, and long-term reliability in demanding environments.

Final Inspection

Completed valves are inspected against drawings, specifications, and customer requirements. This includes dimensional checks, compliance verification, and documentation reviews to ensure full traceability and readiness for dispatch.

Packing & Dispatch

Valves are securely packed and labelled, complete with documentation and certifications. ISPM15-certified cases are available for export, ensuring safe, compliant transport to global project locations.

Starline manufacturing services

Valve Stock & Supply

Valve Automation

Valve Modification

Project Supply

Each valve is supplied with full documentation including material certificates, inspection reports, pressure test records, QC sheets, torque values (if automated), and complete Manufacturing Record Books (MRBs). Project-specific documentation formats can be provided to meet EPC, end-user, or audit requirements.