End-to-End Pipe & Skid Solutions Manufactured in the UK

Fully engineered design, sourcing and assembly of complete pipe and skid packages, delivered with full certification, technical assurance, and ready-to-install performance.

Valves, pipes, design and build

ACV delivers complete, fully engineered pipe and skid assemblies designed to simplify installation, cut lead times, and remove integration risk from your projects. Manufactured in the UK by our in-house engineering team, every package is built to your exact process, material, and documentation requirements — whether you need isolation skids, metering skids, valve assemblies, instrumented packages, or fully welded pipework solutions.

We manage the entire process from design, full product and material sourcing, and welding to actuation, testing, and certification, ensuring full compliance with the latest industry standards. With access to extensive European stock and a global supply network, we can fast-track production, reduce project complexity, and deliver fully assembled, inspected, and ready-to-install skids.

With over 25 years of engineering expertise, we help you reduce installation time, remove procurement headaches, improve system reliability, and gain total confidence that your skid arrives fully compliant, correctly built, and ready to perform from day one.

Benefits we provide

- Supply of bespoke pilot plants

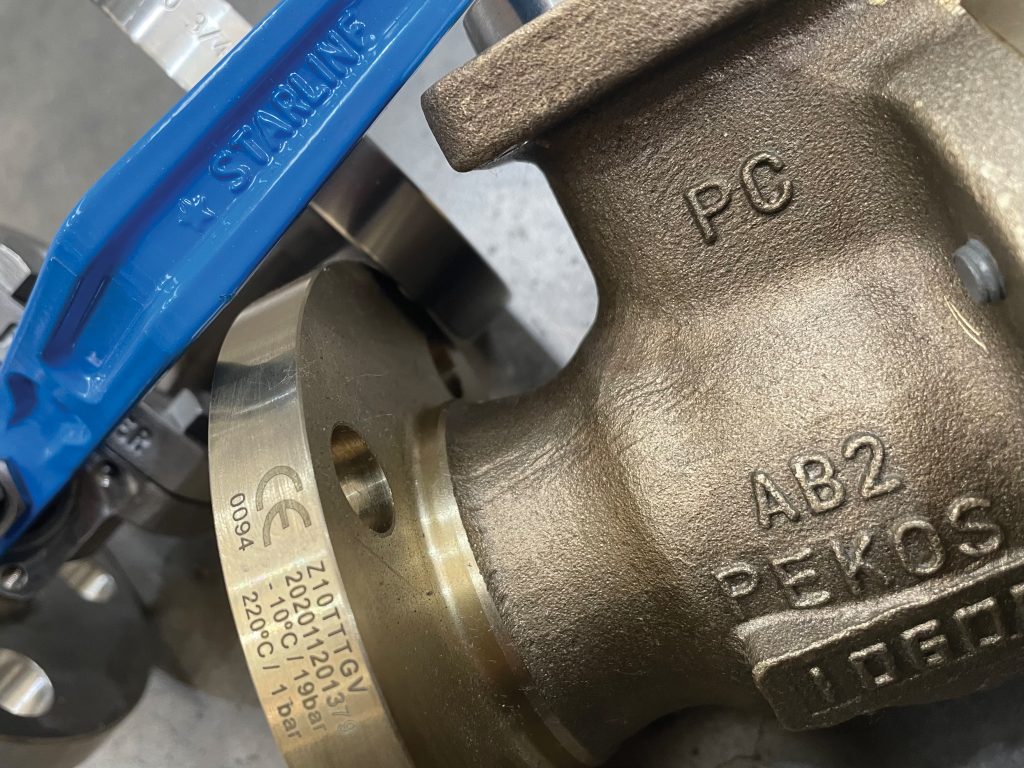

- We build using the most suitable materials, to any pressure and temperature requirements

- We offer fully European material stock options or can source products globally to suit your AVL

- Built to ASME and EN standards

Support we offer

- Product selection and sourcing

- Installation assistance and spare parts

- Plant efficiency

- 3D CAD design

- Large scale projects

- Documentation

- Inspection and testing

Industries we work with

- Carbon capture

- Combustion

- Waste heat recovery

- Energy storage

- Hydrogen

- Oil and gas

- Power generation

- Steel

- General Process

- Water

Pipe & Skid Solutions Team

Jeff Horton

VPS Director

James Carter

Projects and Operations Manager

Falgun Patel

Production Engineer

Pete Mott

Fitter/Fabricator

Thomas Uwins

Fitter

Joshua Hatter

Trainee Fitter

Case study

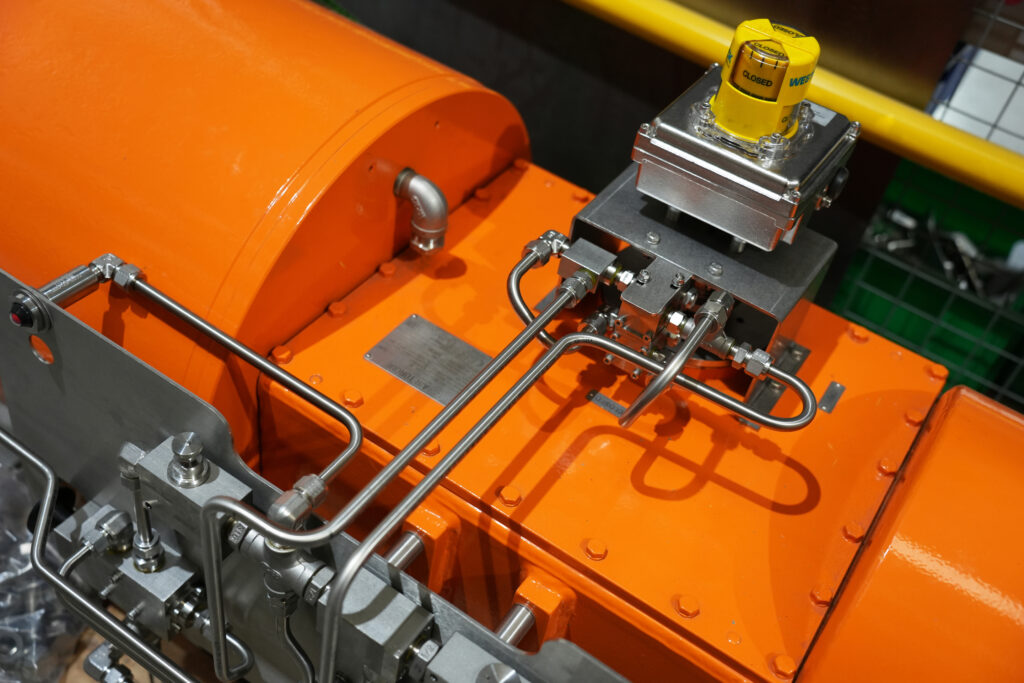

- Built to ASME standard

- Led complete scope and supply of valve and automation package

- Actuated ball valves

- Actuated ball valves

- Pressure regulators

- Y-type strainers

- In-house fabrication of support frame and pipe stools

- In-house Factory Acceptance Testing (FAT) with client inspector

- Full certification package for welding and materials

See how we do it

Our Process

Our pipe and skid process ensures every project is delivered with precision and efficiency, from initial enquiry to final dispatch, combining engineering expertise, quality control, and complete traceability at every stage.

Initial Enquiry

The customer shares project details and specifications. We gather all necessary information, review requirements, timelines, and technical needs to ensure complete understanding of the scope before progressing to design and quotation stages.

Quoting

We prepare a detailed quotation covering materials, labour, and delivery. Any questions or revisions are addressed before finalising costs and securing customer approval to proceed with design, fabrication, and testing.

Design & 3D Modelling

Our engineers create detailed 3D CAD models of the complete pipe and valve skid assembly, ensuring precise fit, functionality, and compliance with all project and customer specifications before fabrication begins.

Fabrication & Assembly

We source materials and components either from our comprehensive stock or our trusted supply network, then fabricate, weld, and assemble the complete skid system. Rigorous quality checks ensure full compliance with drawings, specifications, and engineering standards throughout the process.

Testing

Each system undergoes functional, pressure, and leak testing to confirm safe operation under working conditions. Witnessed Factory Acceptance Testing (FAT) ensures quality and compliance before final approval and dispatch.

Packing & Dispatch

Systems are securely packed, labelled, and documented with all certifications. We arrange delivery or coordinate container loading for collection, offering a cost-effective logistics solution tailored to each customer’s requirements.

Pipe and skid solutions services

Project Supply

Valve Stock & Supply

Valve Automation

Valve Modification

Yes. Every skid is supplied with a complete documentation package, including material certificates, weld logs, NDE reports, inspection records, test certificates, and final manufacturing record books (MRBs). All documents are prepared in your required format and delivered through our controlled document management systems to support full project traceability.