Due to delays with their existing supplier, they needed an immediate solution. We were able to bridge the lead-time gap and provide valves straight off the shelf with minimal waiting time.

Executive Summary

In industrial operations, supply chain interruptions can lead to costly downtime. This case study illustrates how we stepped in to assist a client facing critical delays from their incumbent supplier. By leveraging our extensive off-the-shelf inventory, we provided fully certified, compatible valves immediately, ensuring project continuity.

The Challenge

The customer was in the middle of a time-sensitive project when they encountered a significant setback. Their existing supplier declared an unexpected delay in delivery, pushing the lead time beyond the project’s critical path.

The customer could not afford to wait, but they also could not compromise on quality or technical specifications. Their requirements were strict:

-

Speed: They needed an immediate solution to prevent site downtime.

-

Compliance: All valves required full certification and documentation.

-

Compatibility: The hardware had to integrate seamlessly with existing flanged connections on-site without requiring modification.

The Pain Point: The customer was facing a “lead-time gap”—a dangerous period where the lack of components threatened to stall operations and incur significant costs.

The Solution

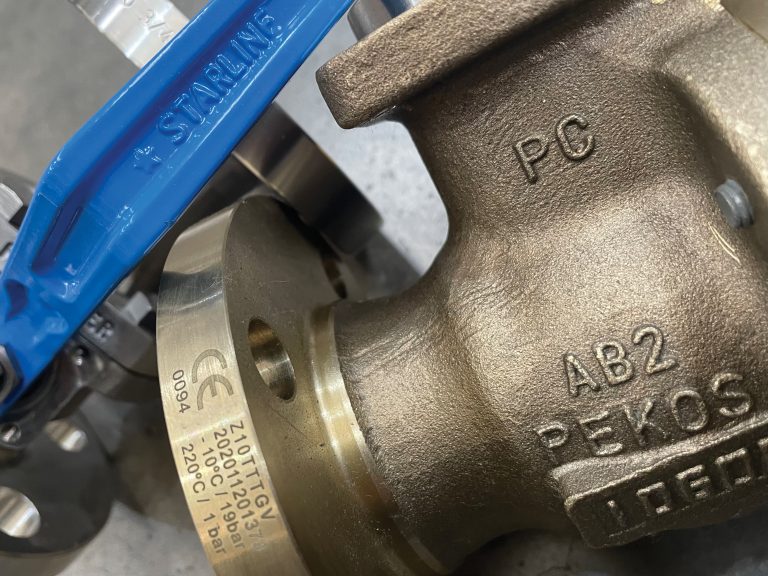

Upon receiving the urgent inquiry, our team immediately assessed the technical specifications of the on-site flanged connections to ensure a perfect match.

Unlike the previous supplier who was manufacturing to order, we were able to leverage our substantial stock holding.

-

Off-the-Shelf Availability: We identified the correct valves within our existing inventory, eliminating the need for manufacturing lead times.

-

Technical Verification: We verified that our stock items were fully compatible with the customer’s specific flanged connections.

-

Certification: We collated and supplied all necessary certification and trace-ability paperwork instantly alongside the hardware.

The Result

We successfully bridged the lead-time gap. By bypassing the manufacturing wait times associated with their original supplier, the customer received their valves with minimal waiting time.

Key outcomes included:

-

Zero Downtime: The immediate supply meant the project continued without interruption.

-

Plug-and-Play Installation: Because we ensured compatibility with existing flanges, installation was fast and error-free.

-

Peace of Mind: The provision of full certification ensured the site remained compliant with safety and quality standards.

Why Choose Us?

This project highlights our core strength: Readiness.

While other suppliers may struggle with supply chain manufacturing delays, our investment in robust stock levels allows us to act as an emergency bridge for our partners. We don’t just sell valves; we sell the assurance that your project will keep moving.