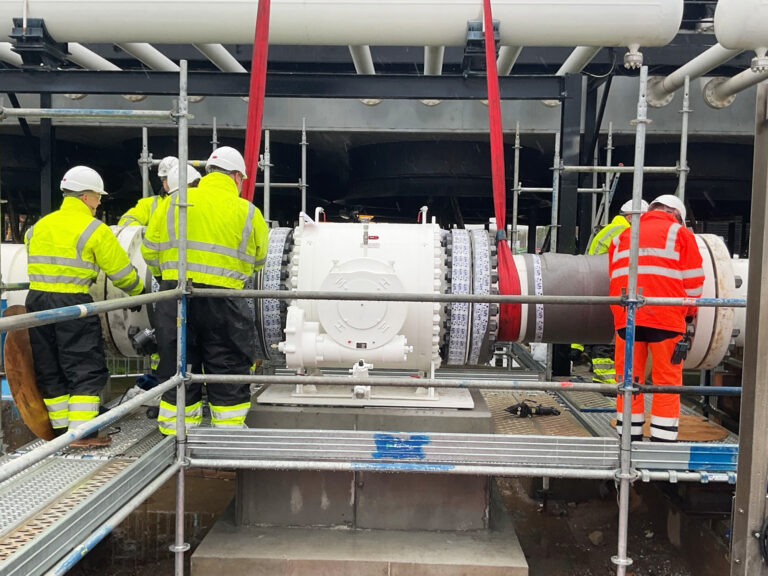

A customer required new aftercooler manifold pipework with specific modifications and the integration of multiple high-performance components, all to a tight delivery schedule.

Using our in-house capability and stock availability, we developed a tailored solution that met the site requirements, machining the valves to the required configuration, optimising installation geometry, and completing all work to the client’s specification before delivery.