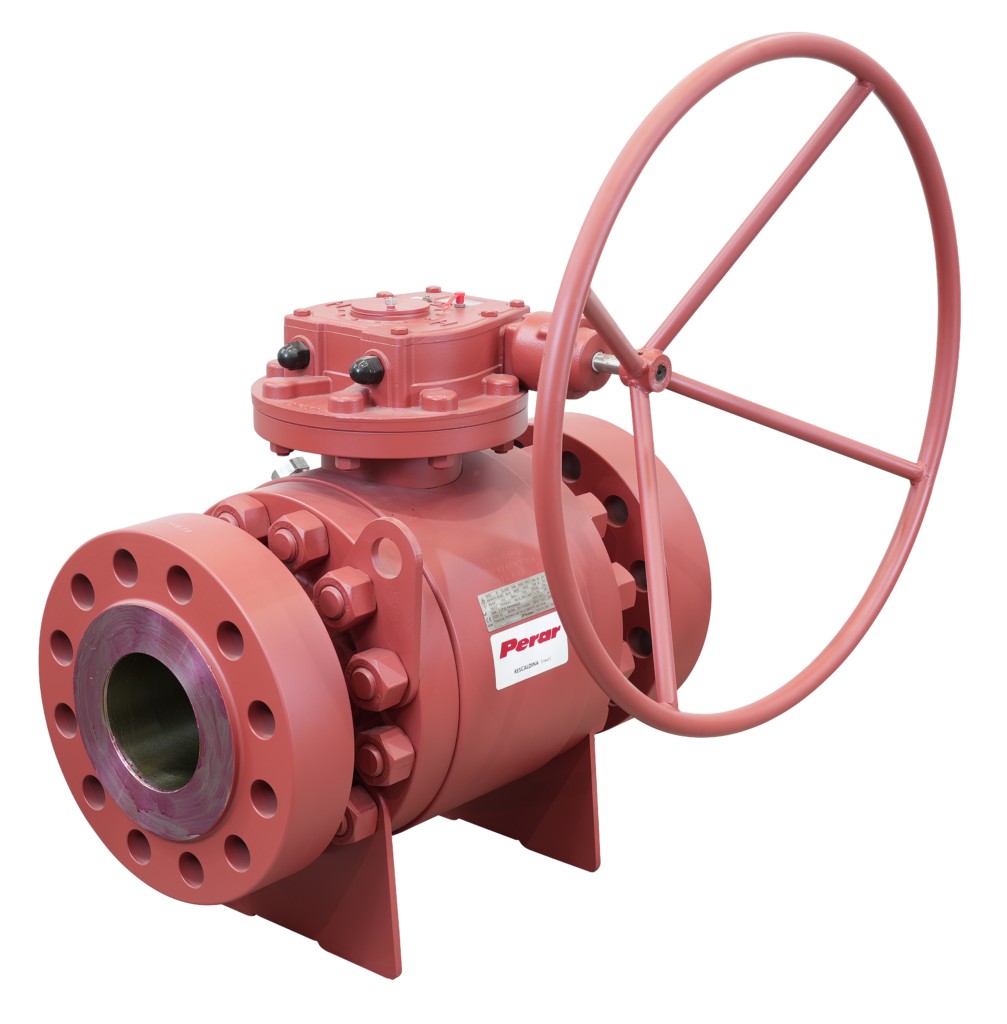

Zwick’s Tri-Con triple offset valves deliver friction-free operation, zero-leakage performance, and exceptional reliability in severe service. Their rigid one-piece body and laminated metal sealing system ensure long service life under high pressure, temperature, and cycling demands. With bi-directional Class VI shut-off, fire-safe and fugitive-emission compliance, and optional Double Block & Bleed, Zwick provides a high-integrity isolation solution trusted across critical process, energy, and pipeline applications.

Zwick

Triple Offset – Tri-Con

Triple eccentric design delivering friction-free operation, zero leakage, and long service life even in severe applications.

Specifications

Size Range

2″ – 88″ (DN 50–2200)

Pressure Class

ANSI 150/300/600/900 and PN 10/16/25/40/63/100/160

Materials

Steel casting, Stainless Steel, Special Alloys

Trim

Laminated stainless steel seal & seat system

Construction

Rigid, heavy-duty one-piece body design

Design

Triple offset geometry; additional Zwick models include: Tri-Shark, Tri-Check, Tri-Block

Seat Inserts

Laminated seal ring, stainless steel seat

Certification

Fire-safe to BS 6755 and API 607 4th ed., Fugitive Emissions to TA-Luft II, SIL 3, EPA 21

Features

Full bi-directional shut-off per API 598 / DIN EN 12266-1; vacuum-tight; optional Double Block & Bleed; high-temperature capability to 815°C

Applications

Oil & Gas, Petrochemical, Chemical, Power, Refining, High-temperature and severe isolation duties

- 2″ – 88″ (DN 50–2200)

- Fully European

- Rigid, heavy-duty one-piece body design

Can’t find the right product?

We supply the full range of butterfly valves.

Get in touch with our team with your requirements.