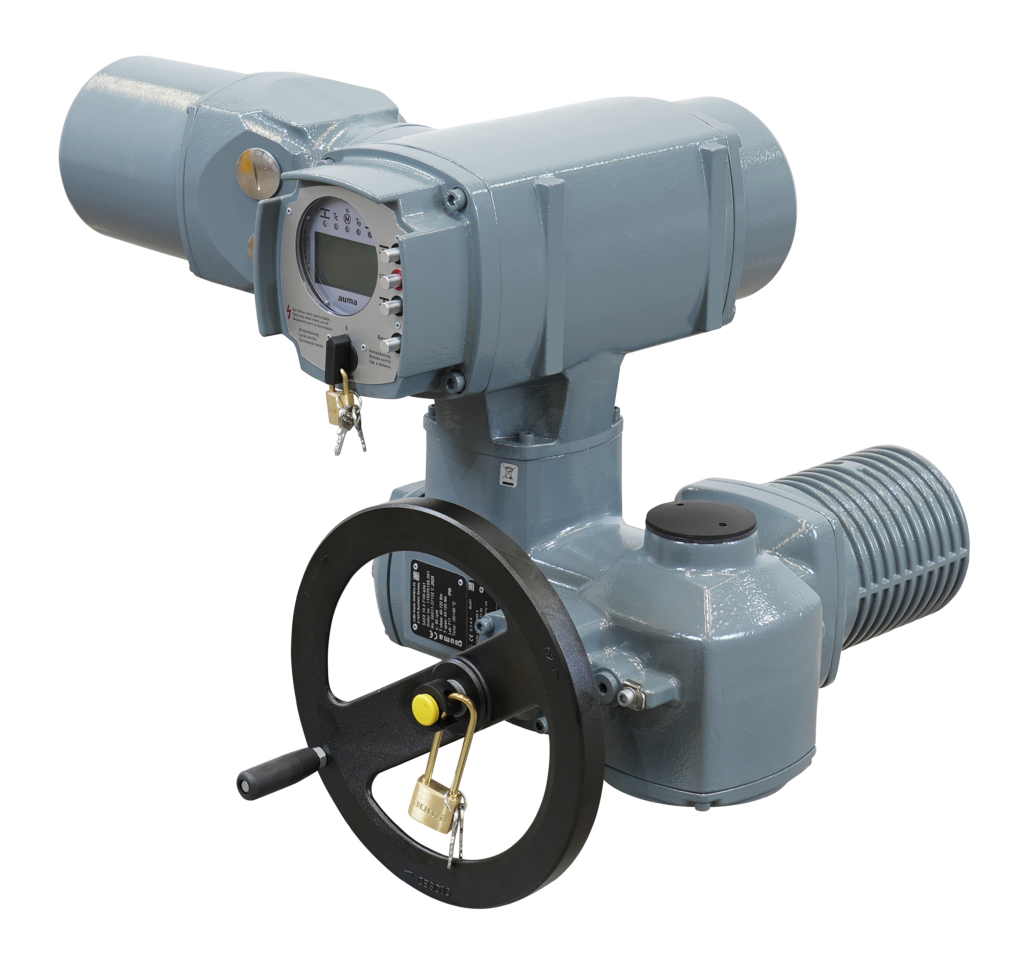

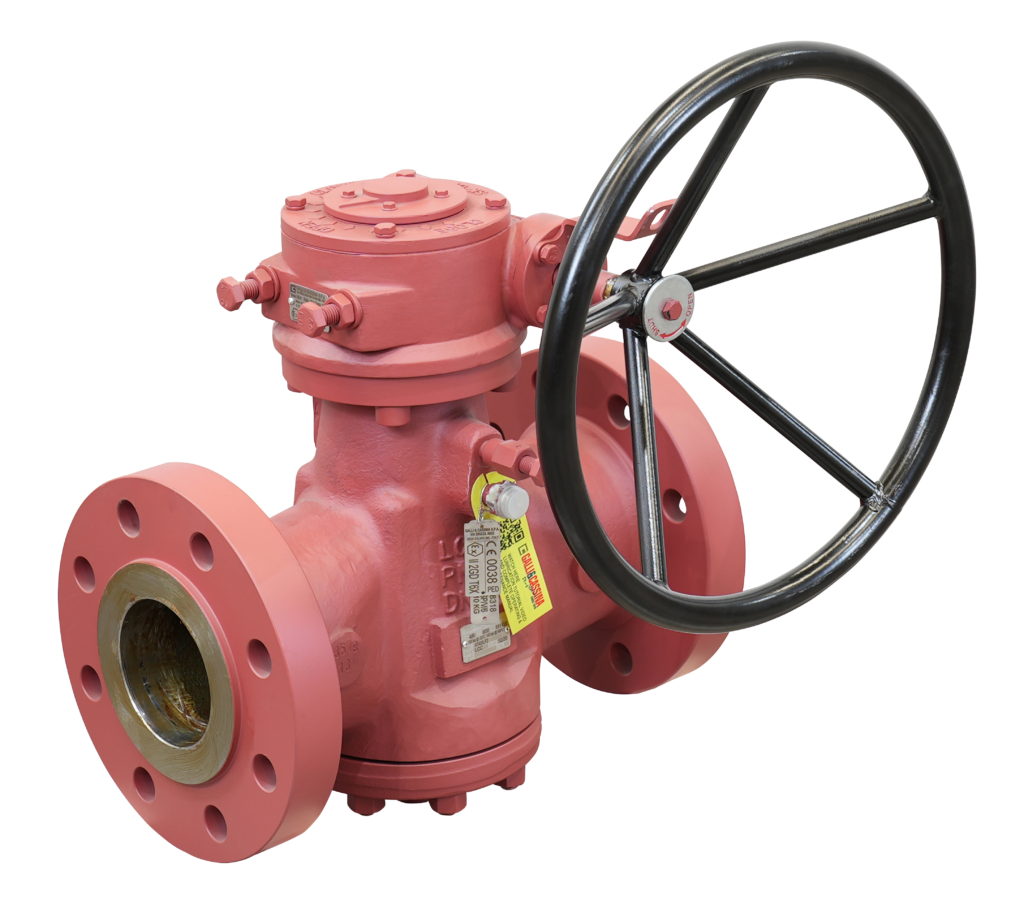

Starline’s top entry trunnion mounted ball valves deliver rapid in-line maintenance, reducing downtime and increasing plant availability in critical service. Their forged construction and high-integrity sealing provide long-term reliability under severe pressure and temperature conditions. With Double Block & Bleed as standard, optional Double Piston Effect, and multiple soft or metal seat technologies, they give operators enhanced safety, tighter shut-off performance, and greater confidence in demanding pipeline and process applications.

Starline

Top Entry Trunnion Mounted Ball Valve

Top entry design for in-line maintenance capability

Specifications

Size Range

1/2" - 36"

Pressure Class

ANSI 150-2500#

Materials

Standard Forged CS LF2, & SS F316/L plus special Alloy materials

Trim

SS 316, & F51 + high tensile strength stem materials available

Construction

Top entry bolted design

Design

API 6D,ANSI B16.34

Seat Inserts

Standard Seats PTFE / RPTFE / Devlon inserts, multiple options available to suit application, including Metal seated

Certification

DNV, Lloyd's register, TUV, TA-Luft,PED, ATEX, SIL3, DVGW, API 6D

Features

Double Block & Bleed as standard, with options for Double Piston Effect execution. Options include emergency sealant, and lip seal designs, forged and cast bodies

Applications

Oil & Gas, Petrochemical, Chemical, Power, Refining, transmission pipelines and critical process isolation duties

- 1/2" - 36"

- Fully European

- ANSI 150-2500#

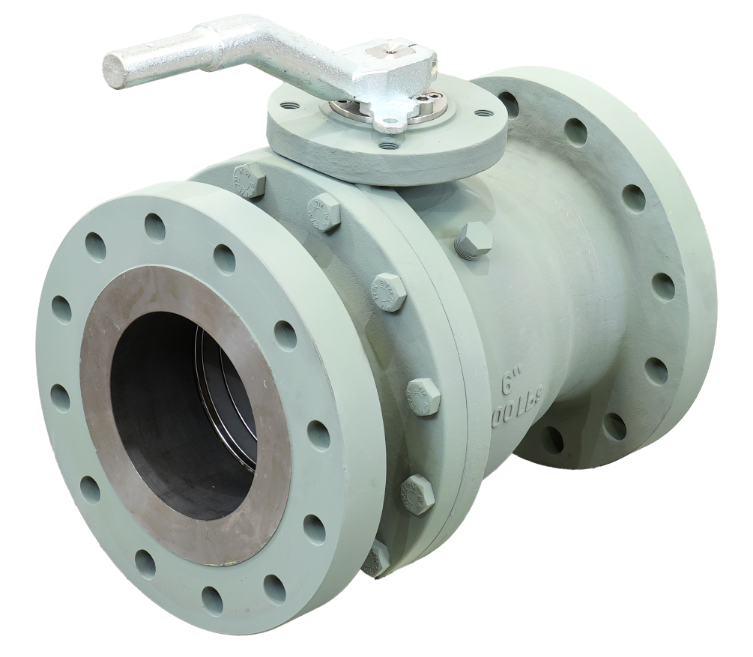

Can’t find the right product?

We supply the full range of Starline valves.

Get in touch with our team with your requirements.