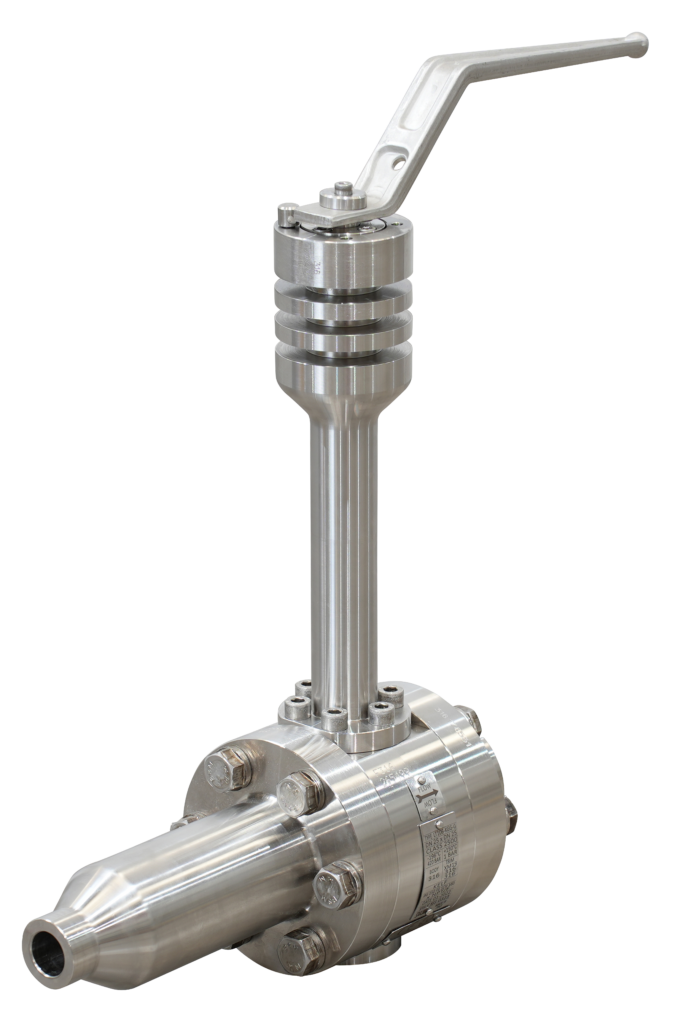

Starline’s soft seated cryogenic floating ball valves provide reliable, zero-leakage isolation in severe low-temperature service, supported by a low-emission stem design and encapsulated seat technology for enhanced sealing integrity. Their extended bonnet ensures safe operation by protecting the stem from cryogenic temperatures, while triple stem sealing and forged stainless steel construction deliver long-term durability. These valves offer dependable, maintenance-friendly performance for LNG, industrial gases and other demanding cryogenic applications.

Starline

Soft Seated Cryogenic Floating Ball Valve

Soft seated design with Zero seat leakage, low emission design as standard.

Specifications

Size Range

1/2" - 6" Full Bore (Refer to size & pressure rating table in product catalogue)

Pressure Class

ANSI 150,300,600,900,1500,2500#

Materials

SS F316/L

Trim

SS F316/ L with options for high tensile strength stem materials

Construction

2-piece & 3-piece bolted body design

Design

API 6D, ANSI B16.34, ISO 17292 (BS 5351)

Seat Inserts

PTFE & PCTFE

Certification

DNV, Lloyd's register, TUV, TA-Luft,PED, ATEX, BS6364, EN 161, SIL3, DVGW, API 6D

Features

Anti Blow out stem, Anti Static device, Self Cavity pressure relief, Triple stem sealing, Low temperature extended bonnet design, unique encapsulated seat design

- 1/2" - 6" Full Bore

- Fully European

- ANSI 150,300,600,900,1500,2500#

Can’t find the right product?

We supply the full range of Starline valves.

Get in touch with our team with your requirements.