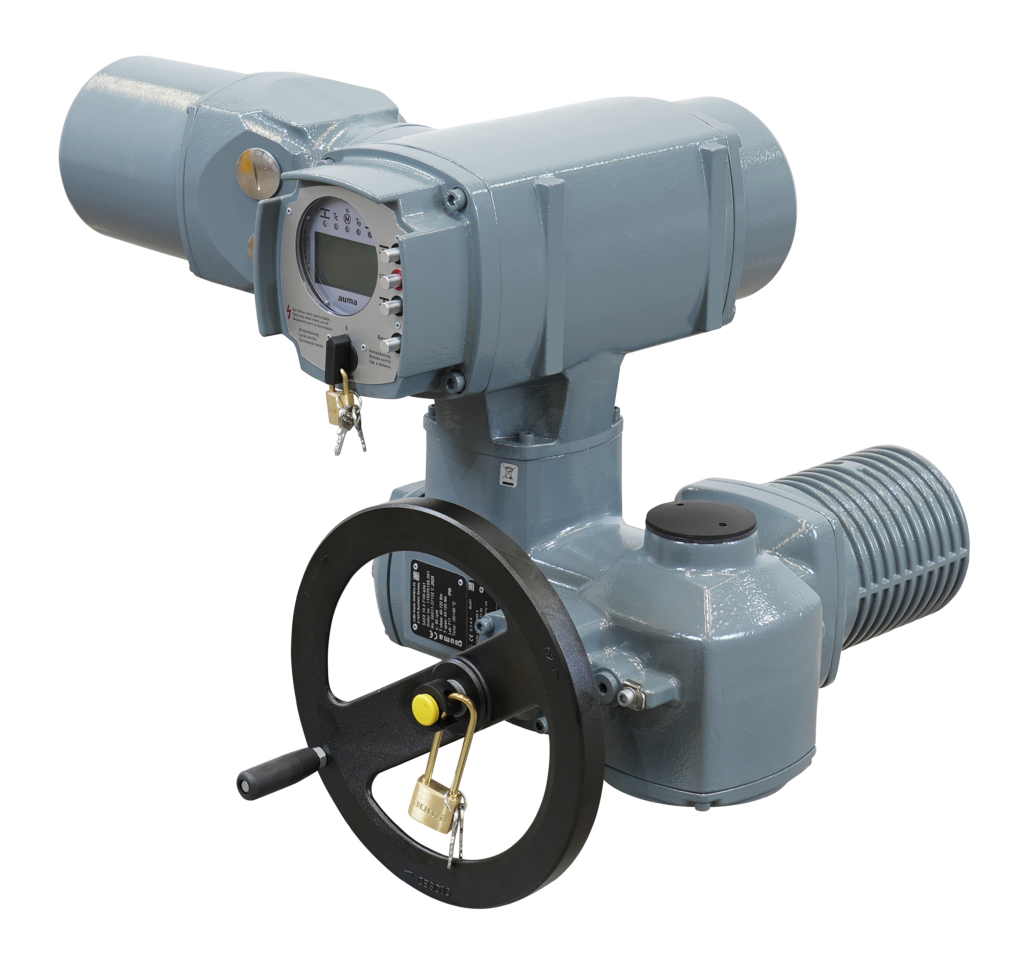

Starline’s metal seated trunnion mounted ball valves provide reliable isolation in extreme temperatures where resilient materials cannot perform. Their hard chrome and tungsten carbide coated ball and seats deliver exceptional wear resistance, low leakage, and long service life in severe conditions. With forged construction, high-integrity trim, and ISO mounting for easy automation, they ensure dependable performance across high-temperature, high-pressure, and demanding process environments.

Starline

Metal Seated Trunnion Mounted Ball Valve for High Temperature Service

Metal seated design with low seat leakage, ISO 5208 Rate A can be guaranteed. ISO Mounting for ease of automation

Specifications

Size Range

1/2" - 36"

Pressure Class

ANSI 150-2500# + API 6A 5000 - 15000

Materials

Standard Forged CS LF2, & SS F316/L plus special Alloy materials

Trim

SS 316, & F51 + high tensile strength stem materials available

Construction

3-Piece bolted

Design

API 6D,ANSI B16.34

Seat Inserts

Chrome & Tungsten Carbide coating to ball & seats

Certification

DNV, Lloyd's register, TUV, TA-Luft,PED, ATEX, EN 161, SIL3, DVGW, API 6D

Features

Designed for operation in temperatures that do not allow the use of resilient materials, supplied with extended stem for insulation.

Applications

Oil & Gas, Petrochemical, Chemical, Power, Refining, high-temperature, high-pressure and severe isolation duties where resilient seats are unsuitable

- 1/2" - 36"

- Fully European

- ANSI 150-2500# + API 6A 5000 - 15000

Can’t find the right product?

We supply the full range of Starline valves.

Get in touch with our team with your requirements.