Sammi line blinds provide safe, verifiable zero-leakage isolation, enabling rapid and controlled blinding without the need for specialised operators. Their heavy-duty fabricated design ensures high reliability in demanding service, while a full range of mechanisms offer flexibility for every installation. With engineered seal options and PED-CE/ATEX models available, they enhance plant safety, reduce isolation risk, and support dependable operation in hazardous, high-risk environments.

ACV Approved Suppliers

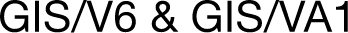

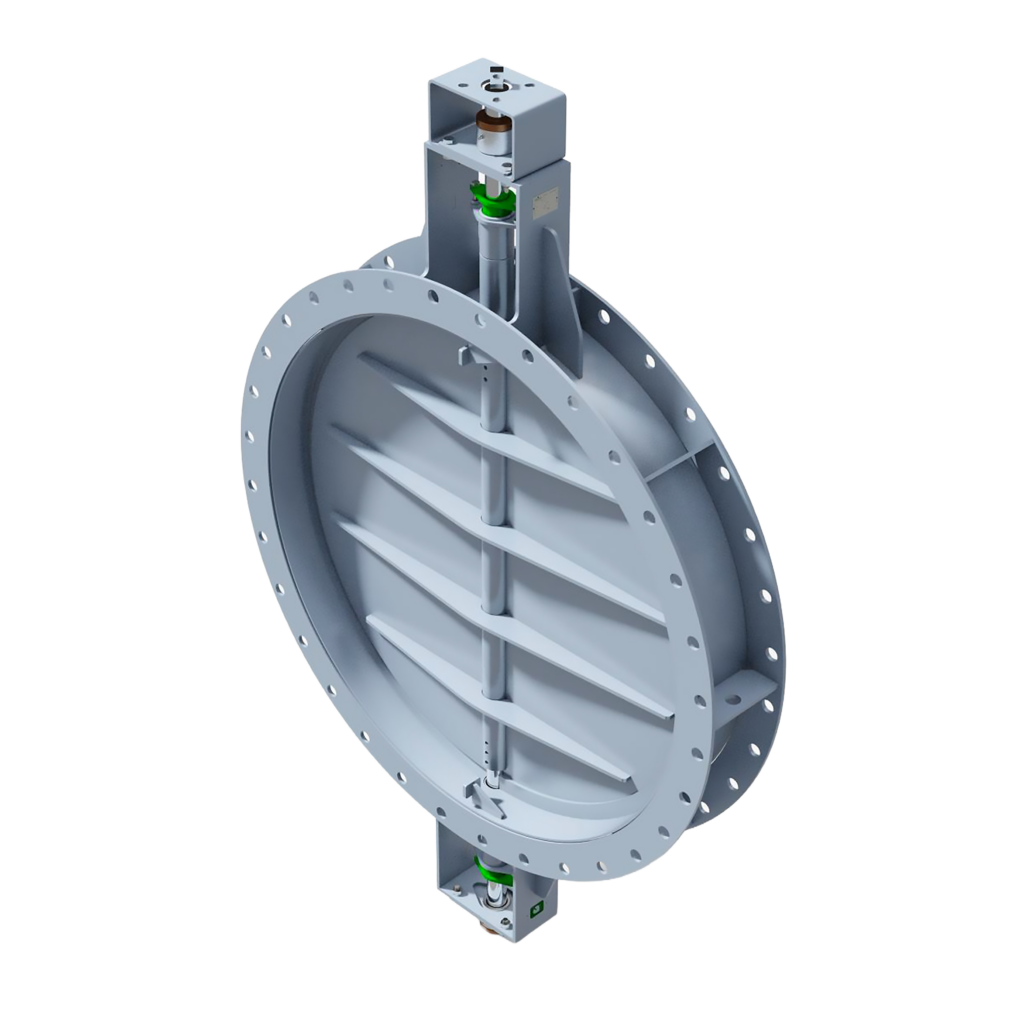

Sammi Line Blinds

High-quality customised engineered line blinds that provide zero leakage and safe and easy blinding by a single untrained operator

Specifications

Size Range

Sizes ½” – 100”

Pressure Class

Class 150# - 1500#

Materials

Carbon Steel, St.Steel, Duplex & exotic alloys

Construction

Heavy-duty fabricated construction

Design

Full range of Sammi designs: Sliding Type, Swing Type, Compact Type, Non-Spill Type, Jack-Bolt Type, Goggle Type, Automated Line Blind, EX-proof Type

Seat Inserts

PTFE, Graphite, Metal seals depending on design and temperature class

Certification

PED-CE Marked (where applicable), ATEX for EX models

Features

Zero-leakage isolation, safe operation, minimal manpower, suitable for hazardous and high-risk environments. Bespoke engineered design.

Applications

Oil & Gas, Petrochemical, Refining, Tank Terminals, Chemical plants, High-risk isolation applications

- Sizes ½” – 100”

- Zero leakage

- Class 150# - 1500#

Can’t find the right product?

We supply the full range of line blind valves.

Get in touch with our team with your requirements.