Nuclear Valves

The main considerations when specifying, buying, or designing valves and associated equipment for the nuclear industry encompass stringent requirements related to safety classification, quality assurance, operational testing, and mitigating known degradation risks, such as those associated with low-flow operation.

Your Trusted Experts for Nuclear Applications

With over 30 years of experience supplying valves to the nuclear industry ACV and its partner suppliers can provide complete end to end solutions for nuclear applications. From one off valve requirements to complete project packages or manufacturing bespoke valves to replace existing equipment or suit special requirements we have a solution for most applications.

Why choose ACV?

Nuclear plant operators want valve suppliers who de-risk their operations

We provide technically correct, fully compliant valves delivered on time, with expert support across the whole lifecycle as a long-term partner rather than a one-off sale.

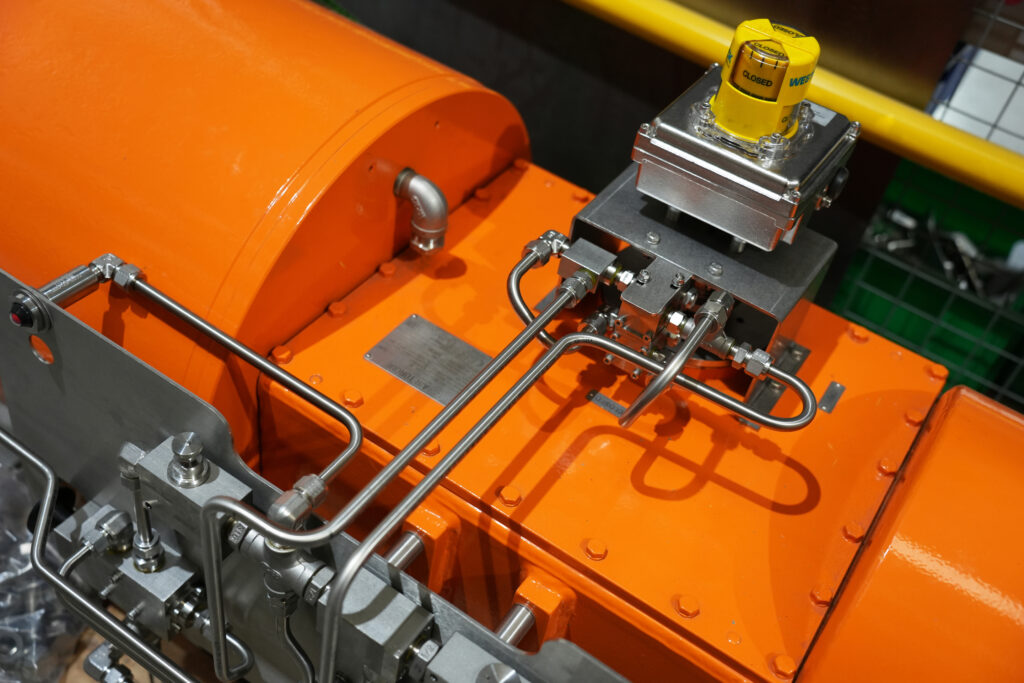

Complete Project Supply

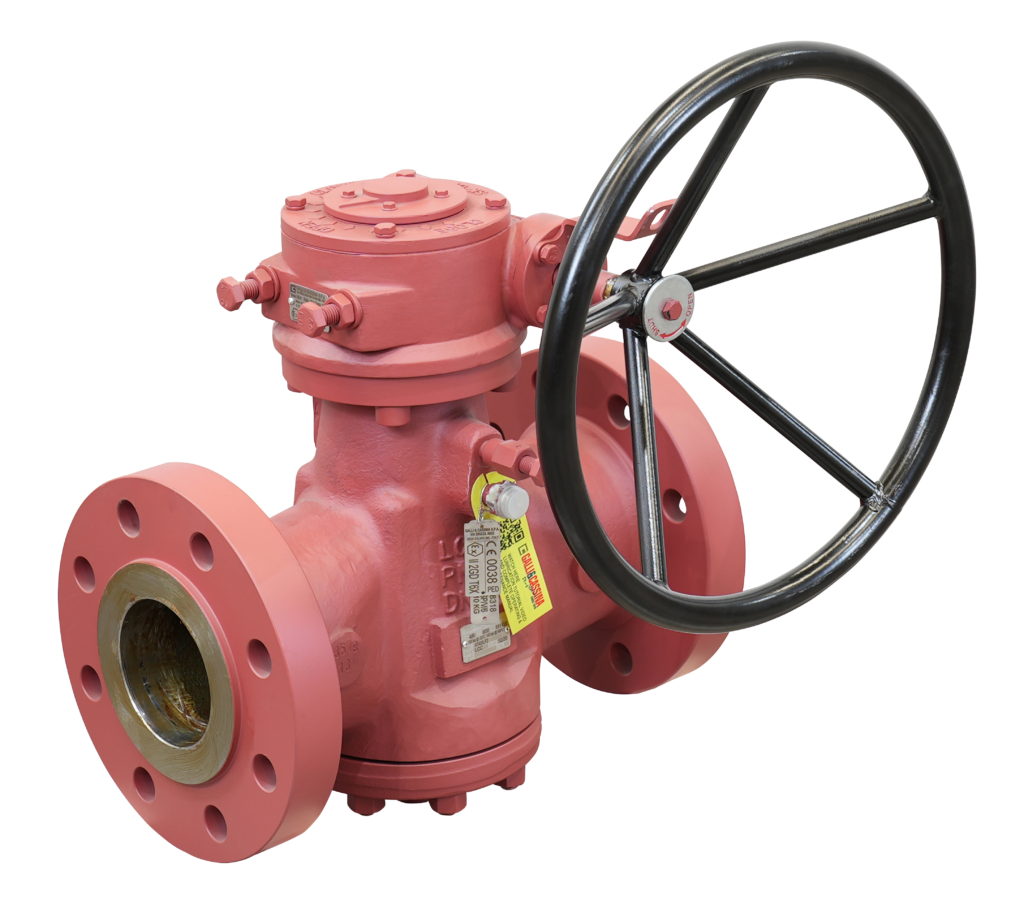

A dedicated projects team means that ACV can supply a complete package of valves, automation, controls and fabricated skids with all required documentation. The ability to source, expedite and inspect globally ACV is a true project partner.

Engineering Support

Our in-house engineering and manufacturing division allows us to modify / upgrade or manufacture products to meet precise requirements meeting both delivery and technical requirements.

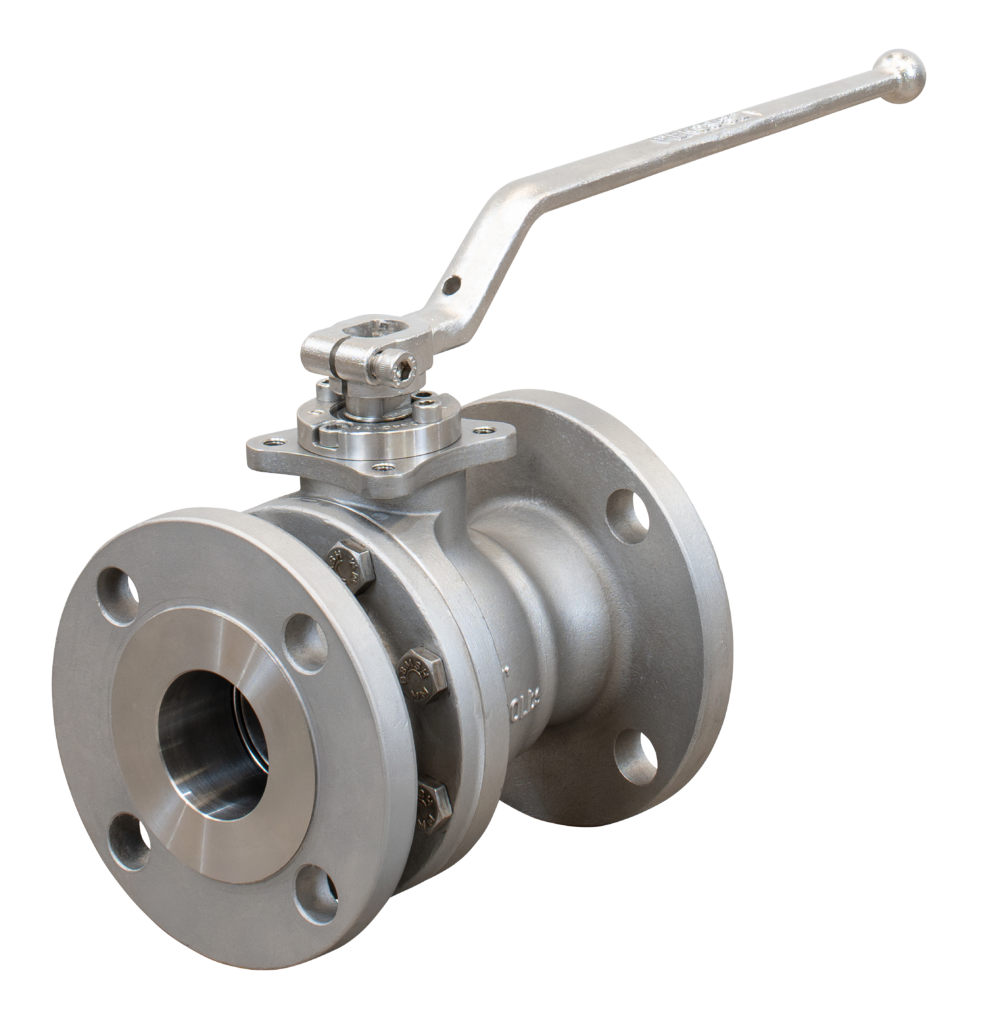

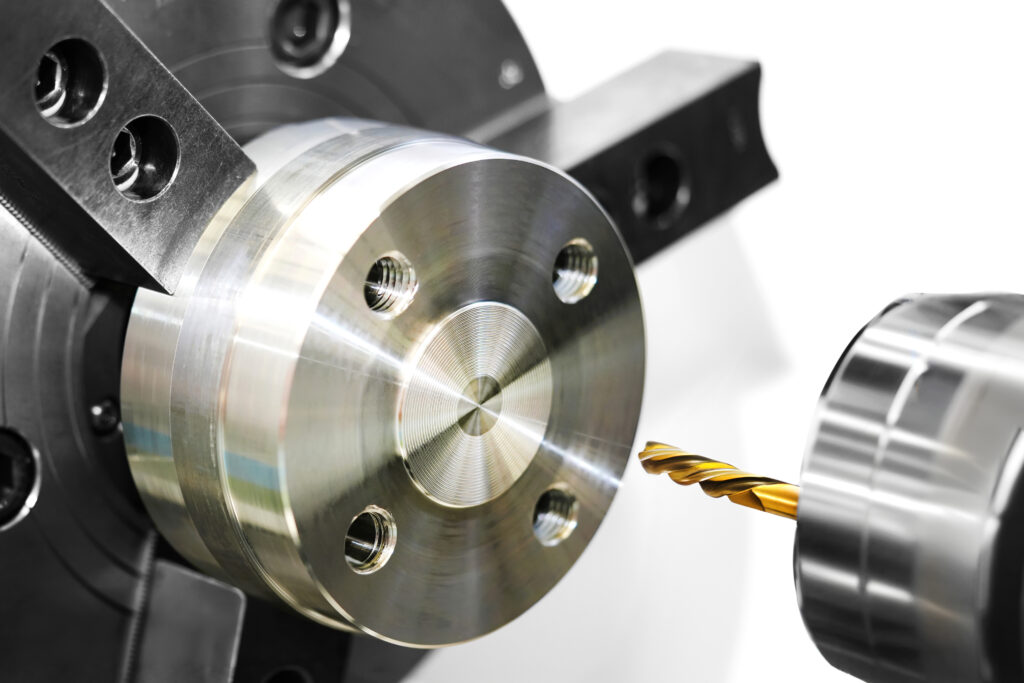

UK Manufactured Valves

At ACV we not only stock a wide range of products but also have the capability to design, manufacture and test valves to meet specific requirements utilising 100% Western European materials specific for nuclear applications.

One of Europe's Largest Valve Stocks For Immediate Delivery

Our large valve stocks allow immediate delivery of ball, plug, butterfly, gate, relief, check, and control valves tailored for nuclear applications along with In-House Customisation & Testing giving the ability to Actuate, modify, and rigorously test products to meet exact customer and international specs and satisfy fast-track delivery requirements. For projects, a dedicated team for quotation, sourcing, expediting and inspection backed up by UK based project engineers, and document controllers to keep complex projects on schedule.

See how we do it

Our Process

We are a problem-solving company, focused on making your projects more efficient, reliable, and cost-effective.

ACV provides a complete, end-to-end solution for valve and automation requirements. From initial project scoping and technical analysis through to final delivery and on-site support, we manage the entire process to reduce risk, simplify procurement, and ensure performance.

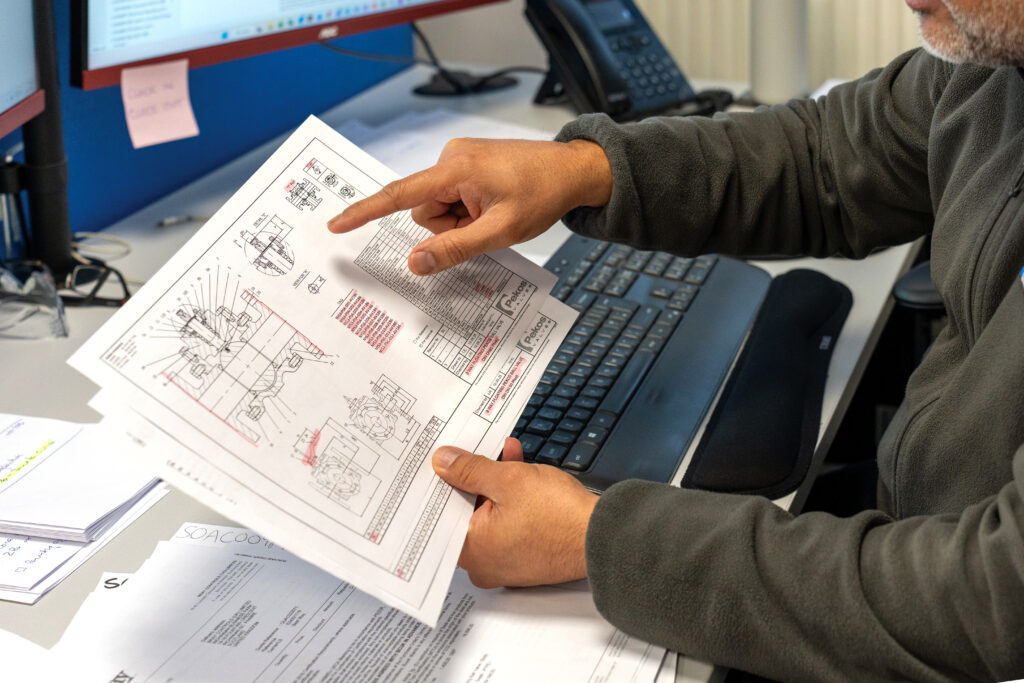

Initial enquiry

Our process begins with a detailed customer enquiry, including project scope, specifications, and any known technical requirements. We gather and review all relevant information to determine the most suitable solution for the application.

Quotation

We provide tailored quotations aligned to project complexity, specification, and timescale. Flexible quotation formats streamline customer evaluation and approval, ensuring clarity, consistency, and efficiency throughout the decision-making process.

Stock & Engineering Solutions

Where possible, we supply directly from stock to support fast-track requirements. We can also modify existing stock or source, design, and manufacture solutions to meet specific application needs. Our engineering expertise ensures products are optimised for pressure, temperature, media, and duty requirements while meeting relevant industry standards.

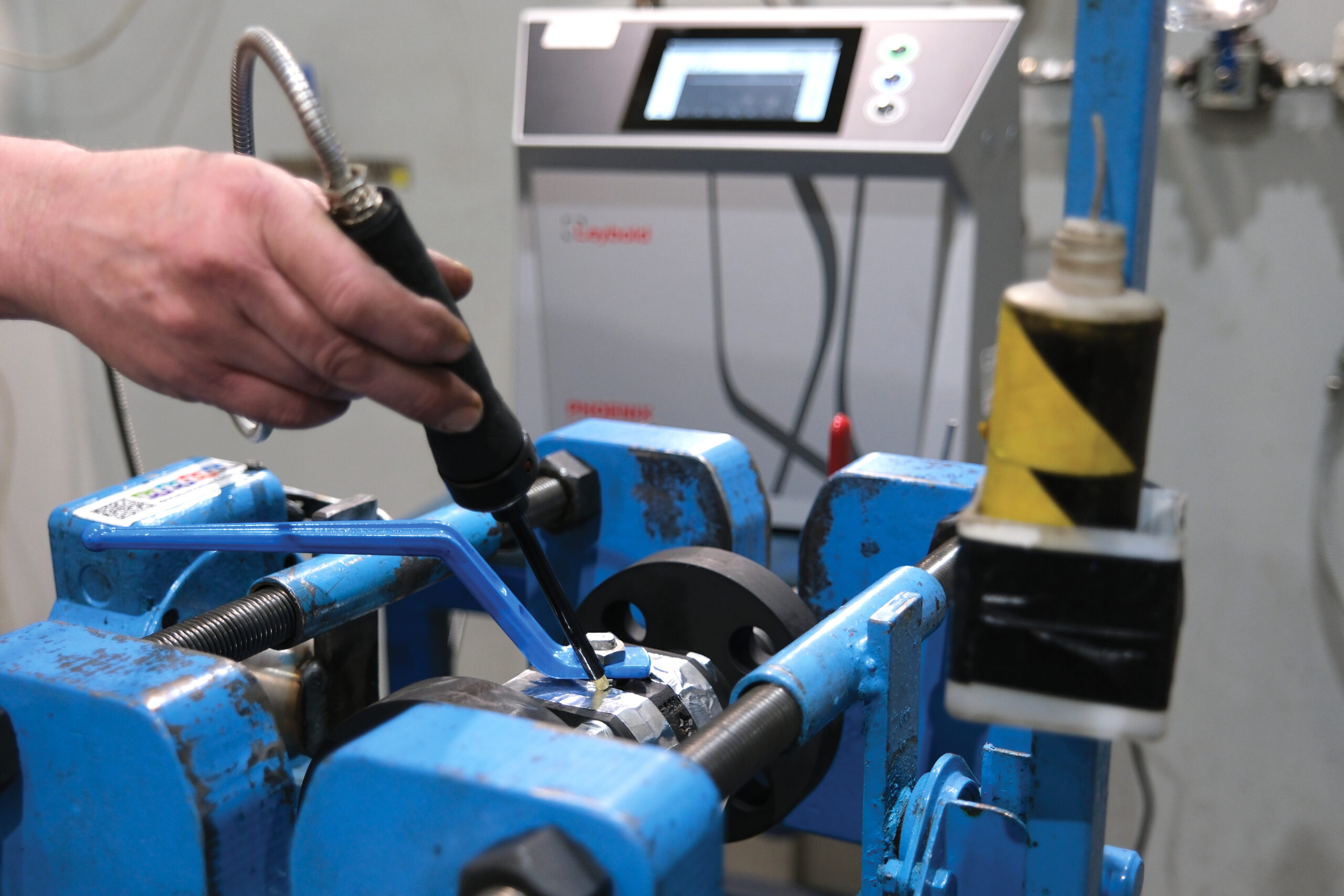

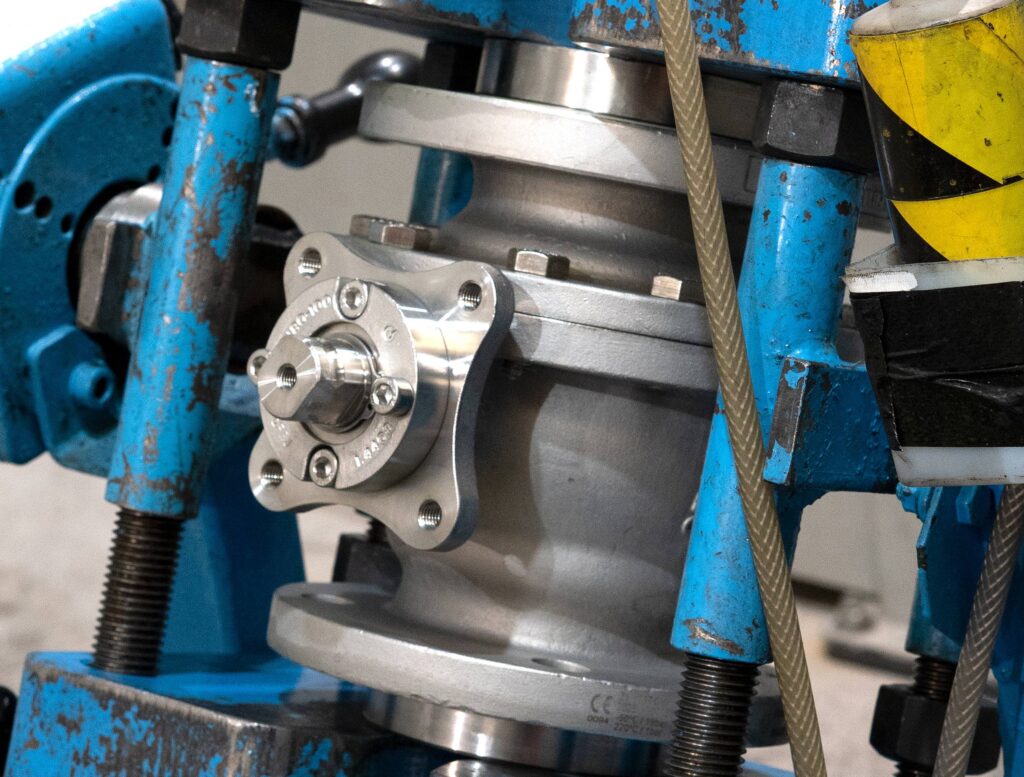

Compliance & Testing

All components undergo rigorous testing in our dedicated facilities to verify performance, integrity, and compliance. Testing regimes are selected to suit the application and may include pressure testing, leak testing, and functional verification to ensure reliability in service.

Order Management

Efficient order management is central to our process. Orders are tracked, coordinated, and fulfilled with care, ensuring correct procedures are followed, milestones are met, and operational integrity is maintained throughout.

Packing & Documentation

Each project is packed in line with customer and project requirements. Full documentation is supplied to support traceability and compliance, including certificates, test reports, and quality documentation as required.

Nuclear valve services

Project Supply

Starline Valve Manufacturing

Valve Automation

Valve Testing

Resources

View all resourcesSolving challenges in nuclear

Challenge

Standard valve testing specifications call for the use of water, air and occasionally Nitrogen when testing valves.

Solution

At ACV Group we have invested heavily in test equipment, ranging from hydrostatic to high pressure nitrogen and on to Helium leak testing measured using our Leybold Phoenix Quadro Helium leak detector which is capable of recording leakages at extremely low levels down to 5.000 × 10⁻¹² mbar·l/s. We will shortly have available specific Hydrogen leak testing to further push the limits of leak detection.

With valves required to operate under a wide range of Pressures, Temperatures and Media ranging from water to complex mixes of high temperature and entrained solids we can evaluate most applications and recommend the correct valve type, materials and configurations to suit.

Challenge

Elastomers and O-rings in nuclear environments must meet specific requirements due to compatibility with the wide range of fluids and pressures which valves may be used on.

Solution

At ACV we hold a substantial stock of all of the main grades of EPDM, Silicone, HNBR, FKM and FFKM elastomers ready for installation to suit precise service requirements. Additionally a wide variety of seat materials are available from PTFE to UHMWPE and PEEK.

From the production of General arrangement drawings to precise quality procedures, technical specifications and full data packages ACV Group understands the importance of correct and accurate documentation, retained for the long terms to support site requirements.

316 typically allows up to about 0.08% carbon, whereas 316L limits carbon to about 0.03%, reducing chromium‑carbide precipitation at grain boundaries during welding or high-temperature exposure. Lower carbon grades like 316L are specifically designed to resist sensitization during normal fabrication and welding, which in turn reduces susceptibility to intergranular corrosion and stress-corrosion cracking in aggressive, high-temperature water chemistries; higher-carbon 316 is more prone to these modes unless solution-annealed and controlled carefully. Valves can be specified as manufactured fully in 316L material, this includes trim components such as Balls and Stems.