Hydrogen

From hydrogen-ready valves to R&D support, we deliver engineered valve and actuation solutions for evolving hydrogen technologies and future-ready energy systems.

Your Trusted Experts for Hydrogen Applications

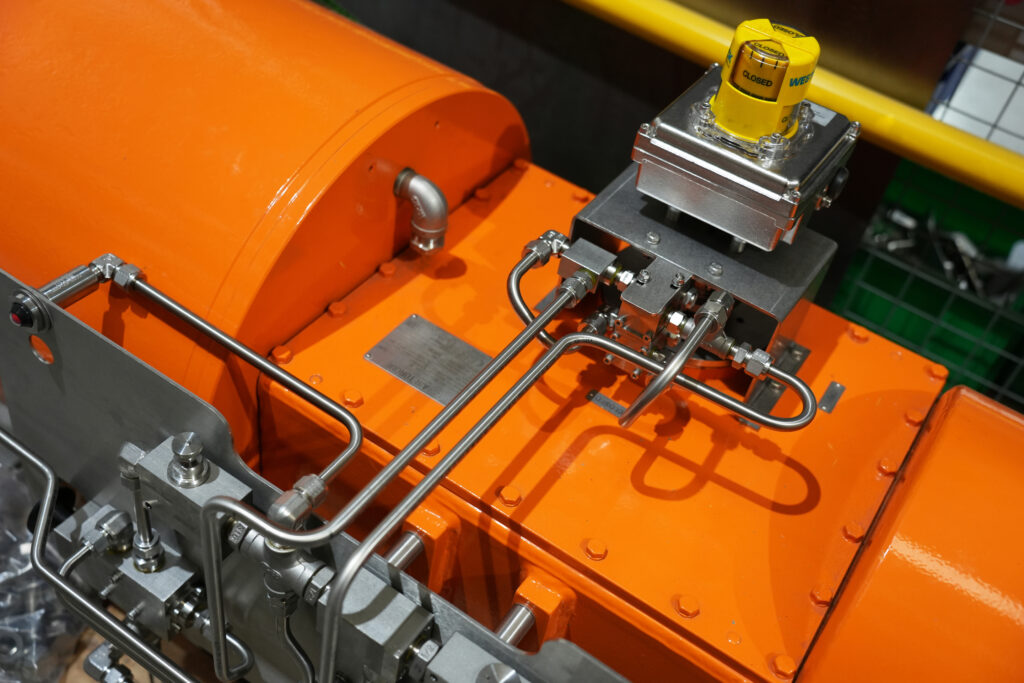

Many hydrogen operators struggle to find a credible valve and actuation partner who truly understands hydrogen media and its challenges. Our engineers bridge that gap with proven expertise in hydrogen-ready valves, valve automation, and system integration. We take a considered, bespoke approach advising on media compatibility, materials, and sealing technologies to ensure safe, efficient, and compliant performance. Both our off-the-shelf and engineered hydrogen valve solutions are fully tested to meet the highest industry standards and your specific project requirements.

Why choose ACV?

Industry Specialists

Both ACV and its core suppliers are specialists in high integrity valves and their applications.

Complete Project Supply

A dedicated projects team means that ACV can supply a complete package of Valves, Automation, controls and fabricated skids with all required documentation.

Hydrogen Testing

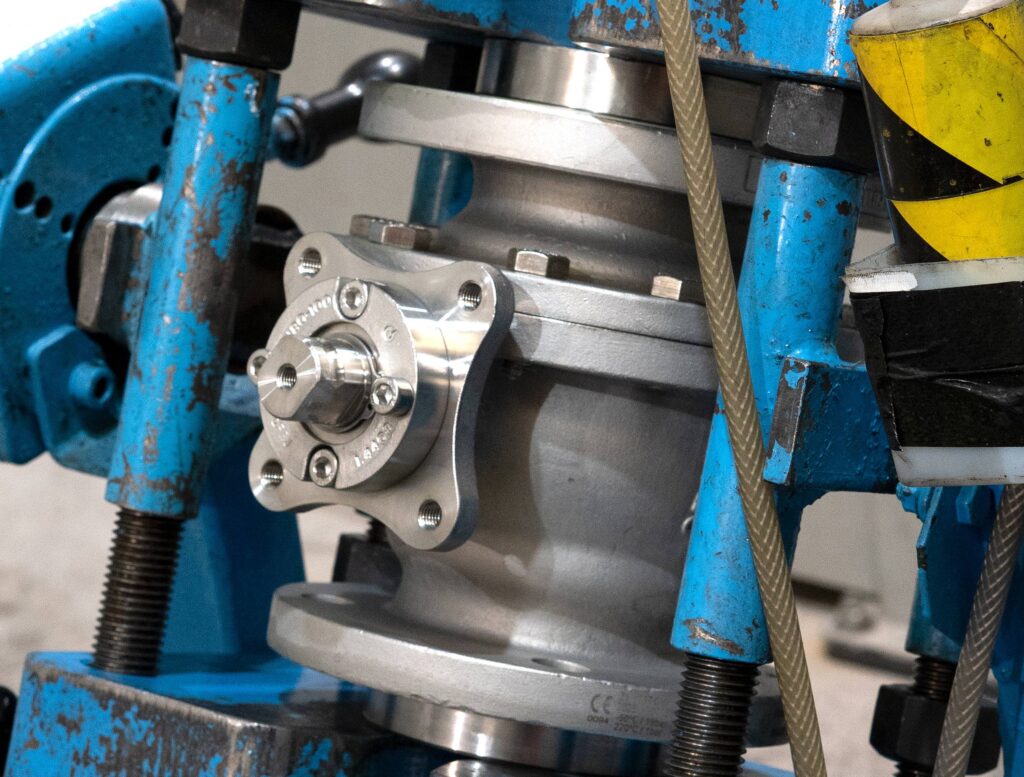

Standard Gas testing is simply not enough for Valves destined for Hydrogen Services, as a minimum valves should be tested on Helium, ideally Hydrogen should be used.

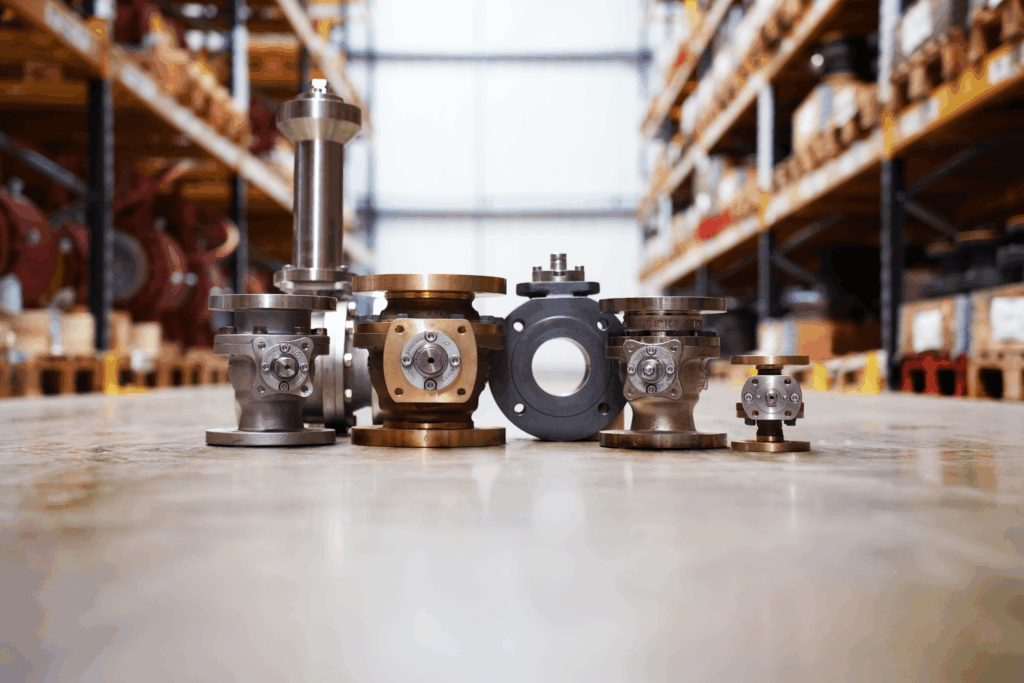

Large Inventory

With factory lead times often being several months, our large inventory combined with our engineering and testing facilities allow fast track delivery of bespoke hydrogen valves.

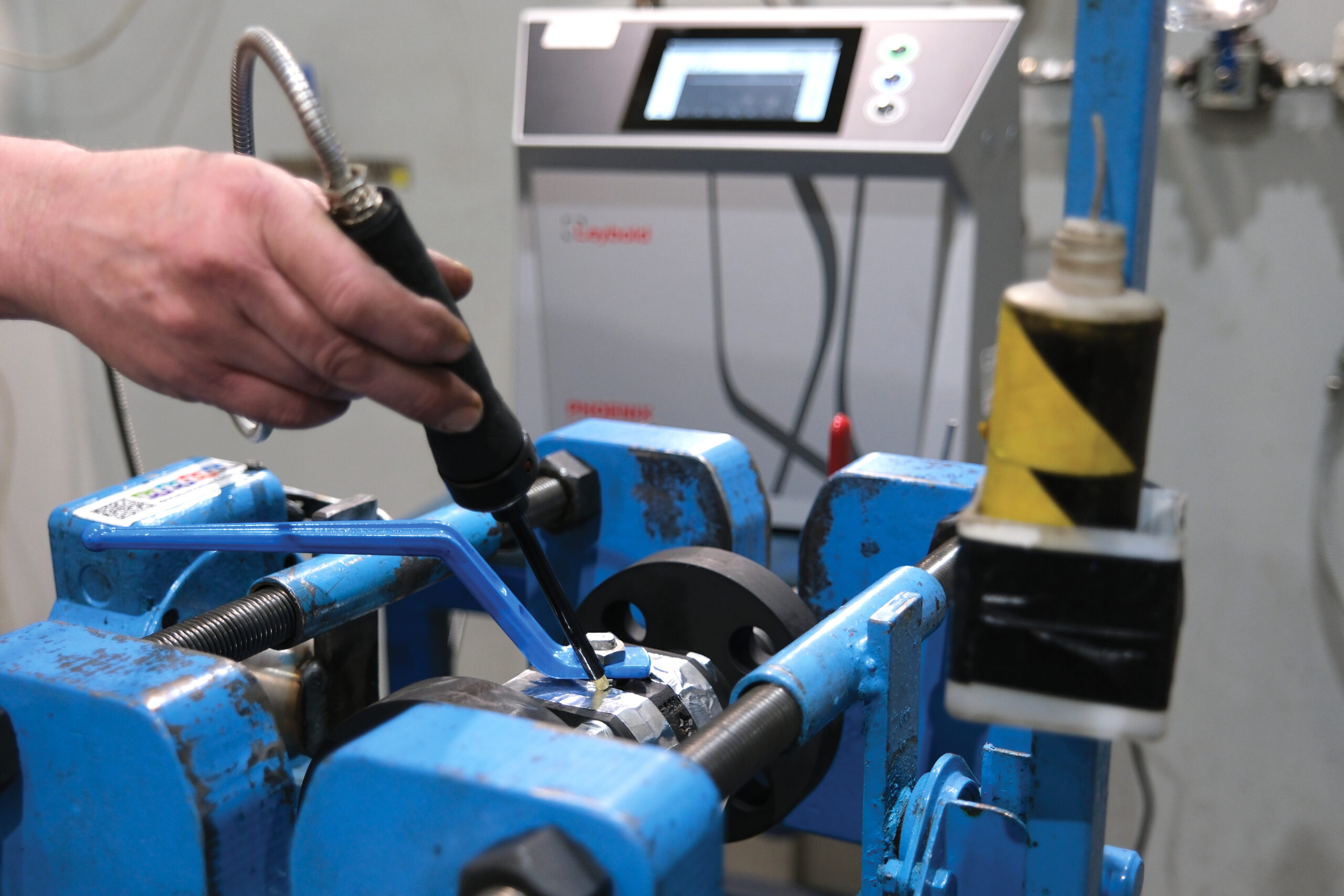

Ultra-sensitive hydrogen leak detection for critical safety applications

Our diffuser sensor testing equipment detects even minimal hydrogen leaks, achieving sensitivity down to 5 x 10⁻¹¹ mbar·l/s for maximum reliability and safety. This exceptional detection capability is crucial given hydrogen’s propensity to escape through the smallest imperfections in seals and joints – leaks that would be undetectable with conventional testing methods but could pose significant safety risks over time.

See how we do it

Our Process

We are a problem-solving company, focused on making your projects more efficient, reliable, and cost-effective.

ACV provides a complete, end-to-end solution for valve and automation requirements. From initial project scoping and technical analysis through to final delivery and on-site support, we manage the entire process to reduce risk, simplify procurement, and ensure performance.

Initial enquiry

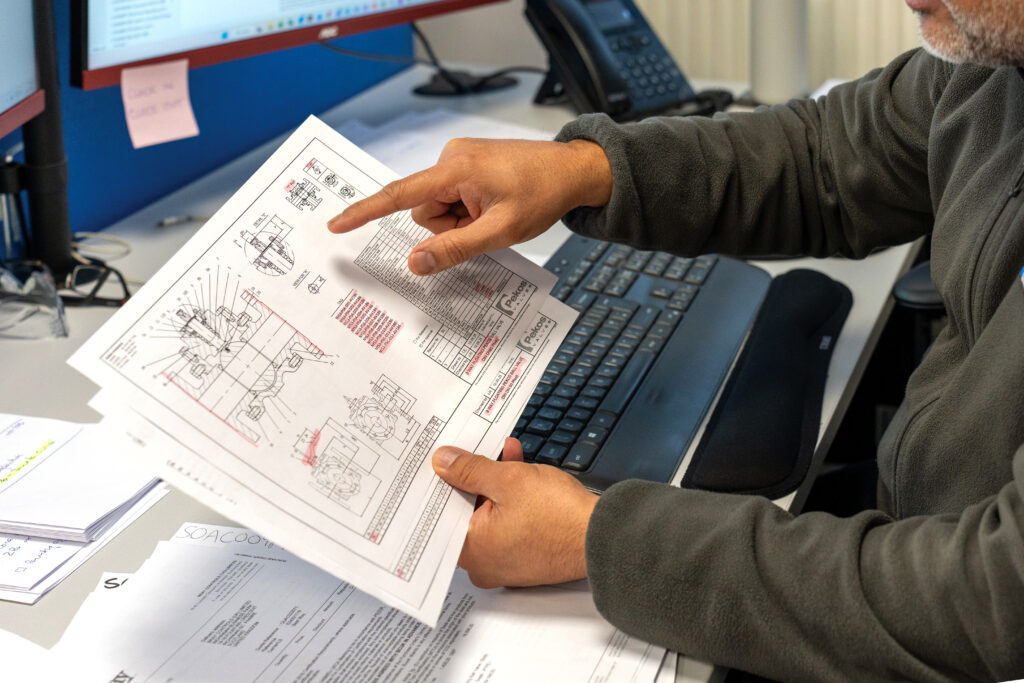

Our process begins with a detailed customer enquiry, including project scope, specifications, and any known technical requirements. We gather and review all relevant information to determine the most suitable solution for the application.

Quotation

We provide tailored quotations aligned to project complexity, specification, and timescale. Flexible quotation formats streamline customer evaluation and approval, ensuring clarity, consistency, and efficiency throughout the decision-making process.

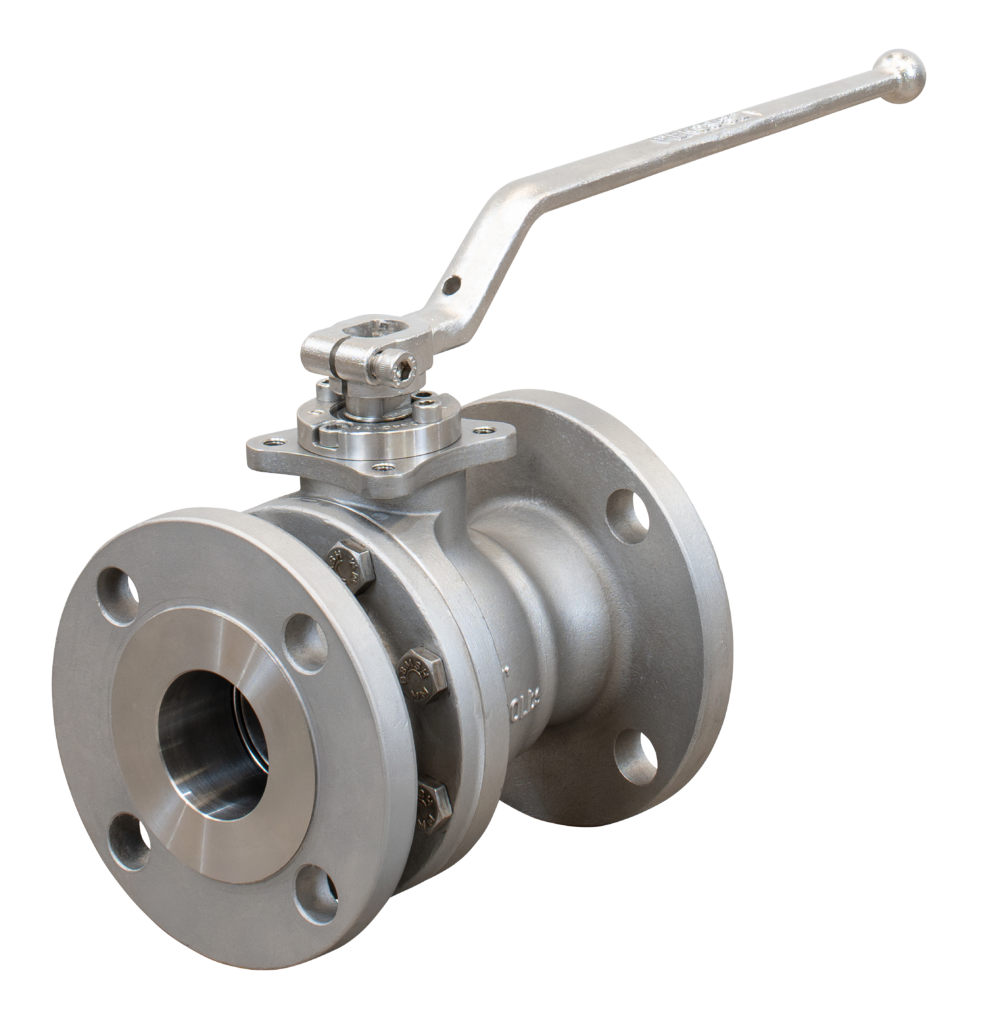

Stock & Engineering Solutions

Where possible, we supply directly from stock to support fast-track requirements. We can also modify existing stock or source, design, and manufacture solutions to meet specific application needs. Our engineering expertise ensures products are optimised for pressure, temperature, media, and duty requirements while meeting relevant industry standards.

Compliance & Testing

All components undergo rigorous testing in our dedicated facilities to verify performance, integrity, and compliance. Testing regimes are selected to suit the application and may include pressure testing, leak testing, and functional verification to ensure reliability in service.

Order Management

Efficient order management is central to our process. Orders are tracked, coordinated, and fulfilled with care, ensuring correct procedures are followed, milestones are met, and operational integrity is maintained throughout.

Packing & Documentation

Each project is packed in line with customer and project requirements. Full documentation is supplied to support traceability and compliance, including certificates, test reports, and quality documentation as required.

Hydrogen valve services

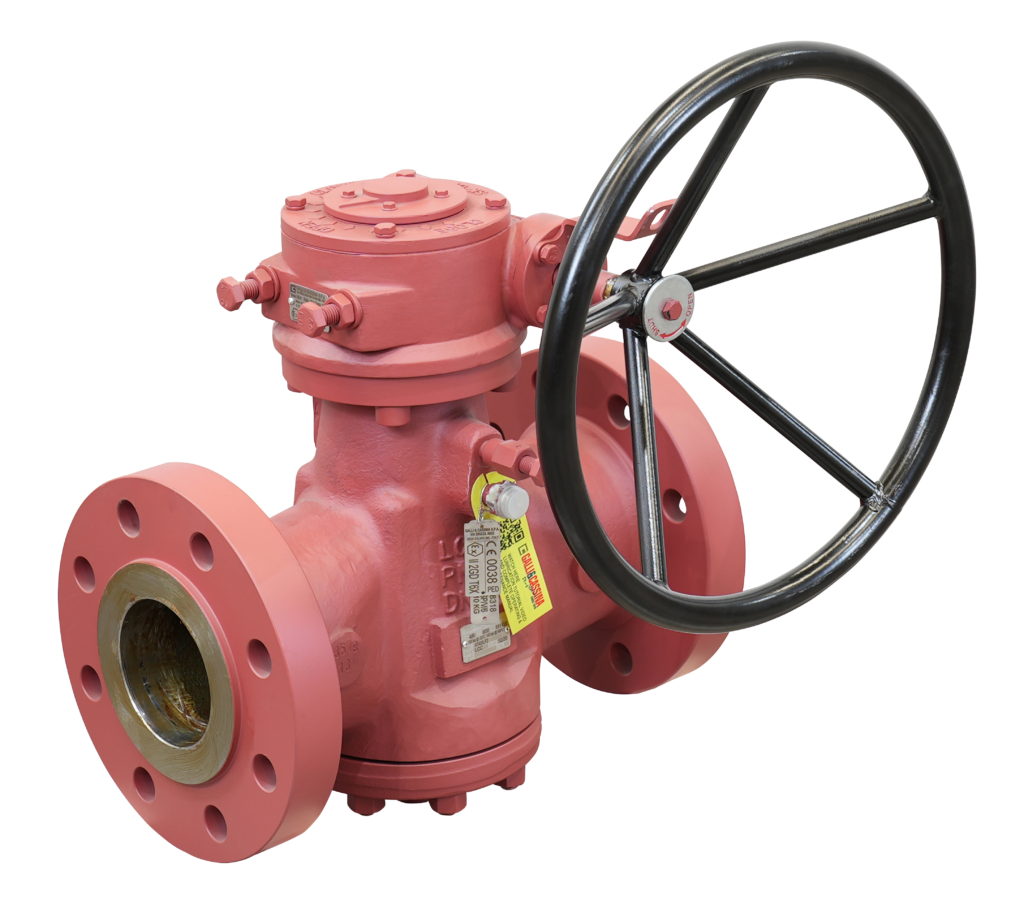

Project Supply

Valve Modification

Valve Automation

Valve Testing

Choosing the right hydrogen valve

The Hydrogen industry produces many challenges for process equipment ranging from High and Low Temperatures to contaminated fluids, corrosion and of course an increased potential for leakage. Material selection for valve bodies, trim and sealing components is essential to ensure correct operation and long, trouble free, service.

Solving valve challenges in hydrogen production and storage

Challenge

Standard valve testing specifications call for the use of water, air and occasionally Nitrogen when testing valves.

Solution

At ACV Group we have invested heavily in test equipment, as a base level all valves specified for hydrogen service are tested using Helium gas and leakage measured using our Leybold Phoenix Quadro Helium leak detector which is capable of recording leakages at extremely low levels down to 5.000 × 10⁻¹² mbar·l/s. We will shortly have available specific Hydrogen leak testing to further push the limits of leak detection.

Challenge

Lubricants, Seals or packing materials can contaminate hydrogen, compromising purity crucial for fuel cells or chemical processes.

Solution

We ensure that Seats and Seals are carefully selected to ensure compatibility with Hydrogen. Where necessary valves are degreased and fitted with correct seal combinations and designs.

Challenge

Elastomers and O-rings in hydrogen-rich environments must meet specific requirements due to hydrogen’s unique physical and chemical properties

Solution

It is important to consider the full service conditions in order to select the correct elastomers. EPDM, has good chemical compatibility but does suffer from permeability, HNBR has good mechanical resistance but can suffer with aging and FKM can stiffen at higher temperatures. One of the best performing materials is FFKM, but there is a significant cost implication. At ACV Group we hold a substantial stock of all grades ready for installation to suit precise service requirements.

Challenge

Valve stems can fail due to material incompatibility with hydrogen, causing operational failures even if actuators work properly.

Solution

As standard our products generally have stems in 316 stainless steel which is one of the best, cost effective solutions for Hydrogen service. Where higher strength is required we hold Alloy 718 and Nitronic 50 (XM-19) options where higher torques need to be passed. Materials such as Carbon Steels and 17,4ph should be avoided due to are them being susceptible to hydrogen-induced cracking and embrittlement.

Using validated materials, proper surface treatments, advanced sealing designs, and rigorous testing minimize failure risks and extend valve life.