Carbon Capture and Storage

For the carbon capture and storage (CCS) industry, piping equipment and valves must meet stringent requirements due to the unique properties and operational conditions of CO₂ transport and injection.

Carbon Dioxide

Valves for CCS must be carefully selected and designed to handle high pressure, corrosive impurities, variable CO₂ phases, and safety-critical leak prevention. Solutions centre around material choice, robust sealing, bespoke valve engineering, and system integration with modern control technologies. These measures address the challenges to enable reliable, safe, and efficient CO₂ capture, transport, and storage infrastructure.

Why choose ACV?

Industry Specialists

With almost 30 years of experience in the field, ACV and its core suppliers have supplied high integrity valves into the oil, gas, and petrochemical industries.

Complete Project Supply

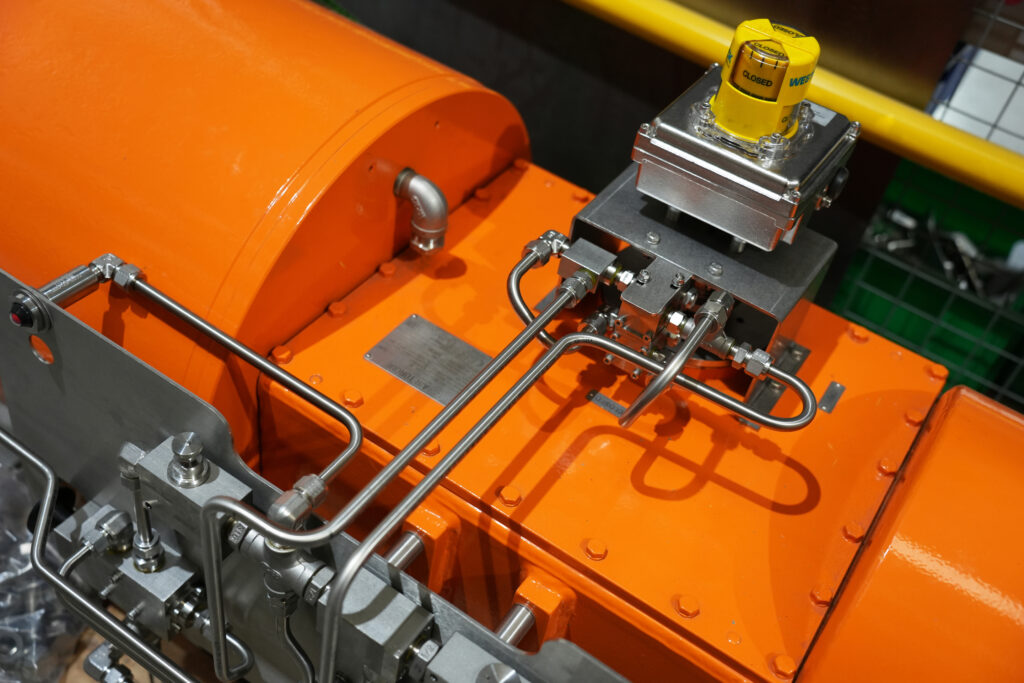

A dedicated projects team means that ACV can supply a complete package of valves, automation, controls, and fabricated skids with all required documentation.

Comprehensive Inventory

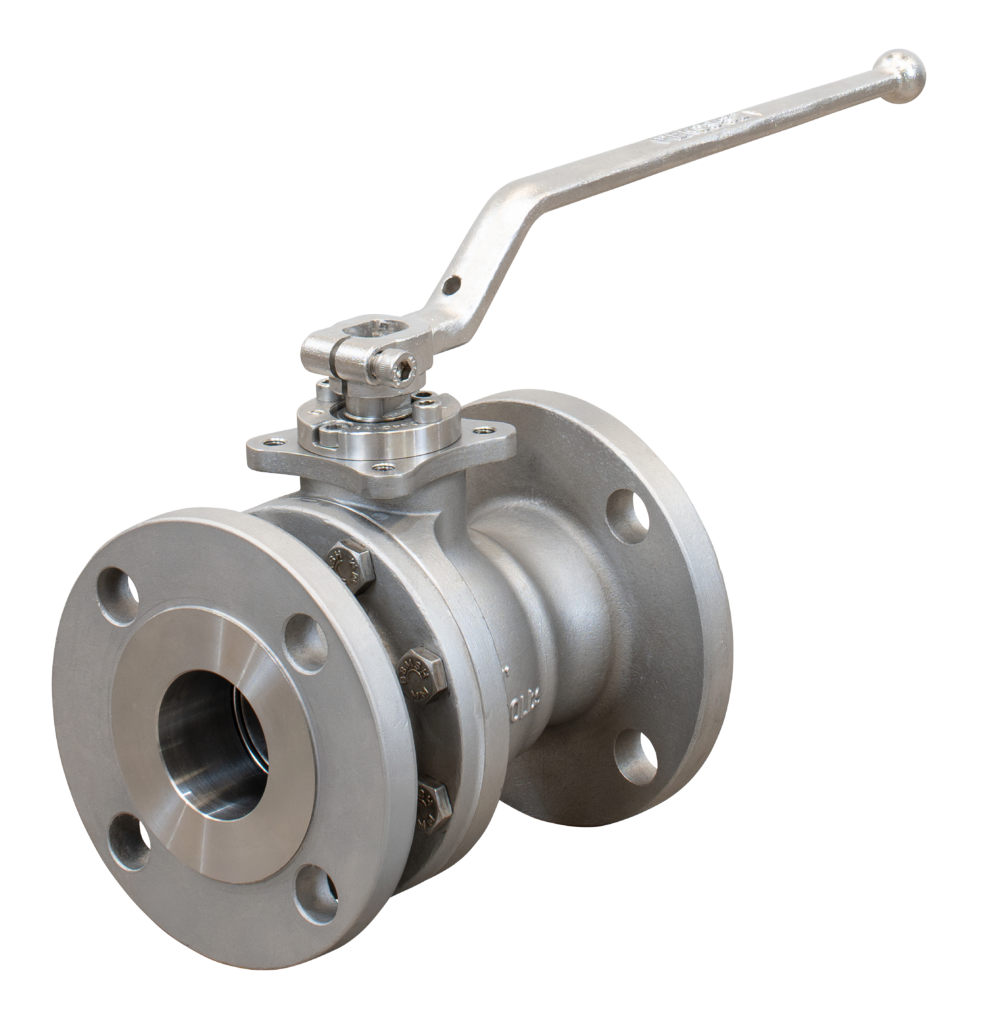

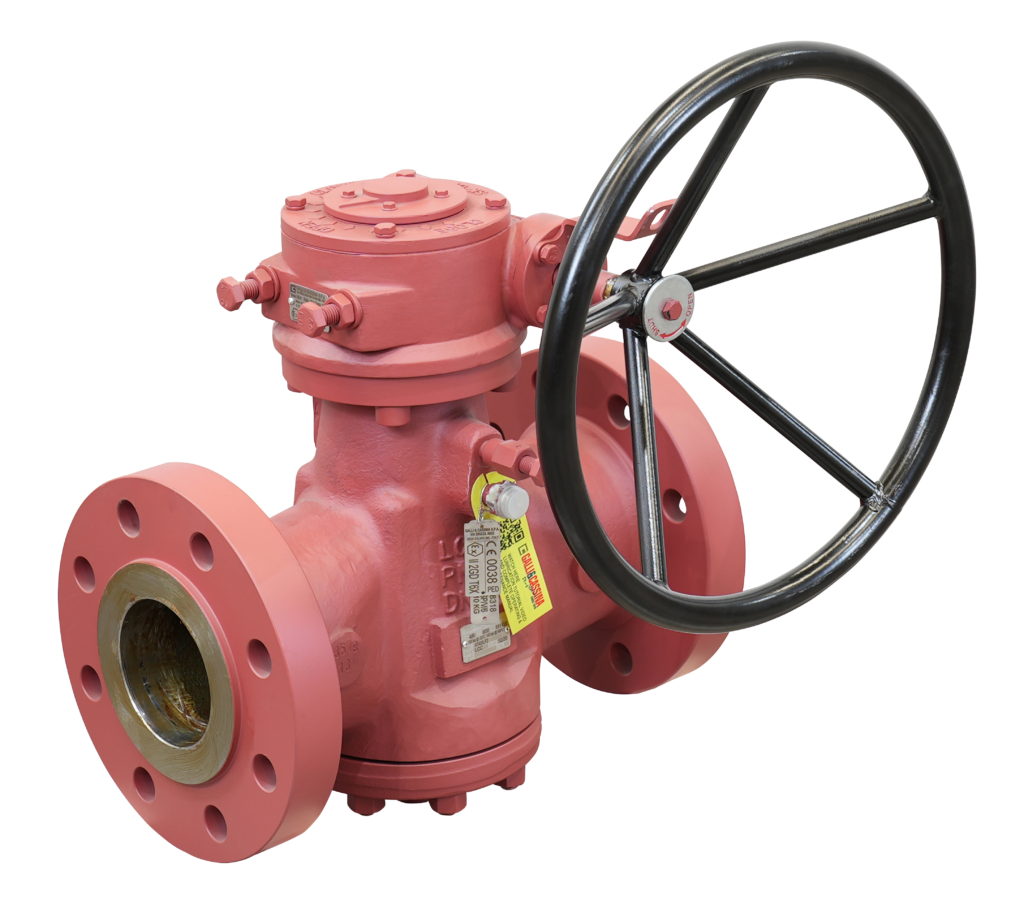

One of Europe’s largest stocks, predominantly of ball valves, supported by a huge inventory of components held at our principal suppliers’ manufacturing plants.

Engineering Support

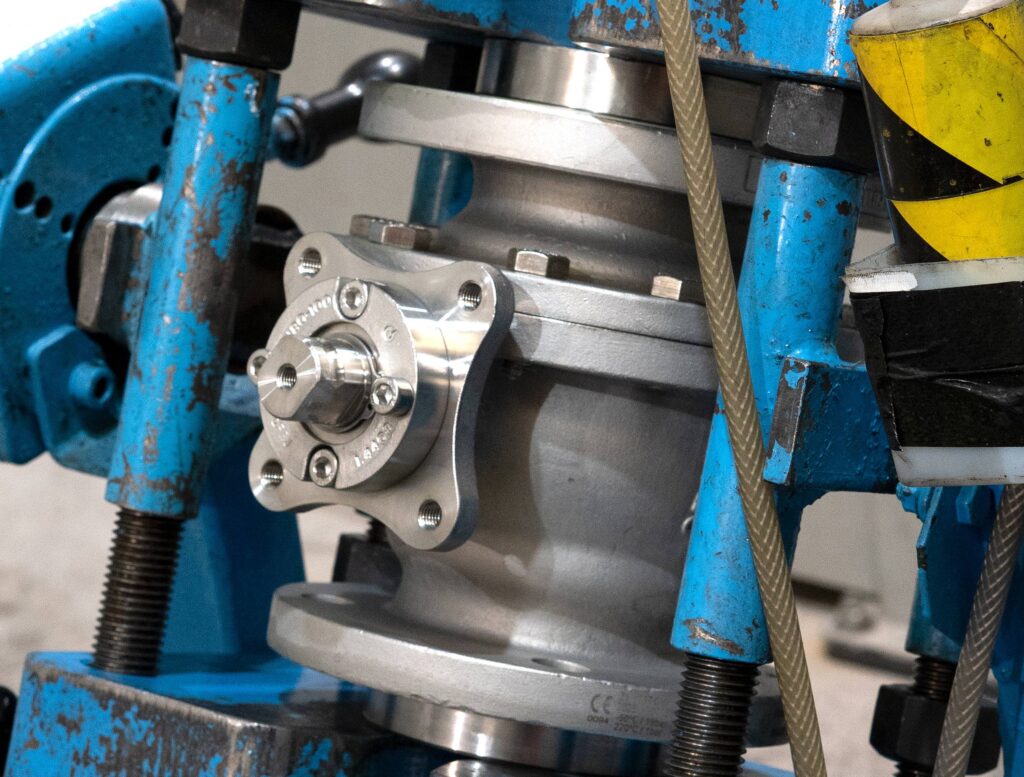

Our in-house engineering and manufacturing division allows us to manufacture, modify or upgrade products to meet both delivery and technical requirements.

Europe’s largest valve inventory

ACV has immediate access to floating/trunnion ball, DBB/DI plug, triple-offset butterfly, gate, safety relief, check, and control valves – slashing lead times from months to days.

Our in-house experts can rapidly modify, actuate, and test valves, adhering to your site specifications for seamless integration.

A dedicated team covering worldwide sourcing, expedition, inspection, UK engineering, and document control keeps complex projects on track, on time, and within budget.

See how we do it

Our Process

We are a problem-solving company, focused on making your projects more efficient, reliable, and cost-effective.

ACV provides a complete, end-to-end solution for valve and automation requirements. From initial project scoping and technical analysis through to final delivery and on-site support, we manage the entire process to reduce risk, simplify procurement, and ensure performance.

Initial enquiry

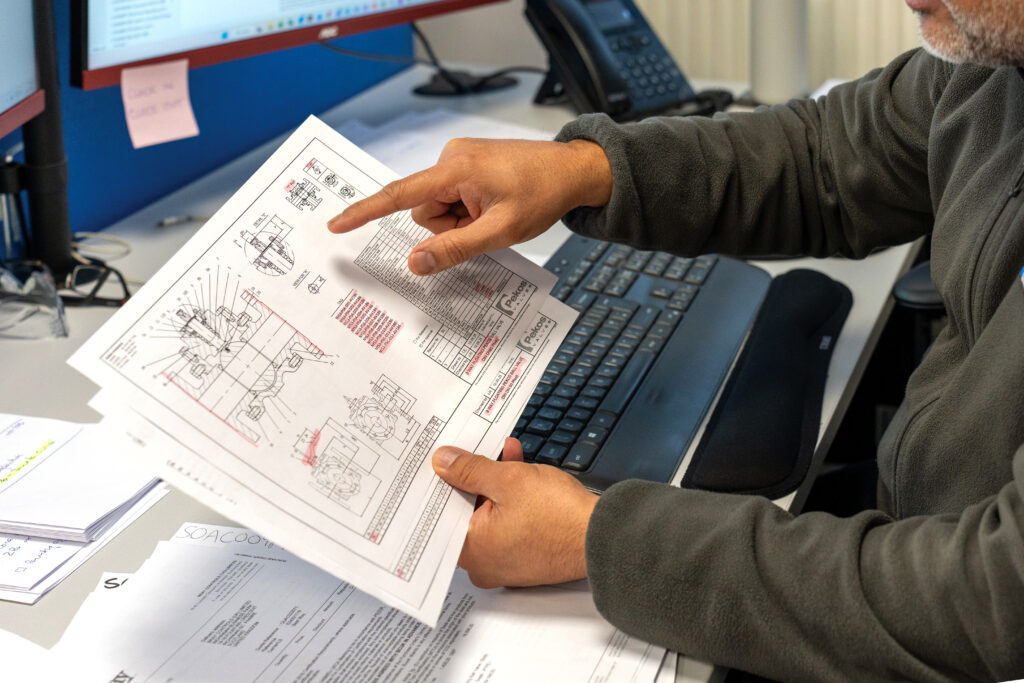

Our process begins with a detailed customer enquiry, including project scope, specifications, and any known technical requirements. We gather and review all relevant information to determine the most suitable solution for the application.

Quotation

We provide tailored quotations aligned to project complexity, specification, and timescale. Flexible quotation formats streamline customer evaluation and approval, ensuring clarity, consistency, and efficiency throughout the decision-making process.

Stock & Engineering Solutions

Where possible, we supply directly from stock to support fast-track requirements. We can also modify existing stock or source, design, and manufacture solutions to meet specific application needs. Our engineering expertise ensures products are optimised for pressure, temperature, media, and duty requirements while meeting relevant industry standards.

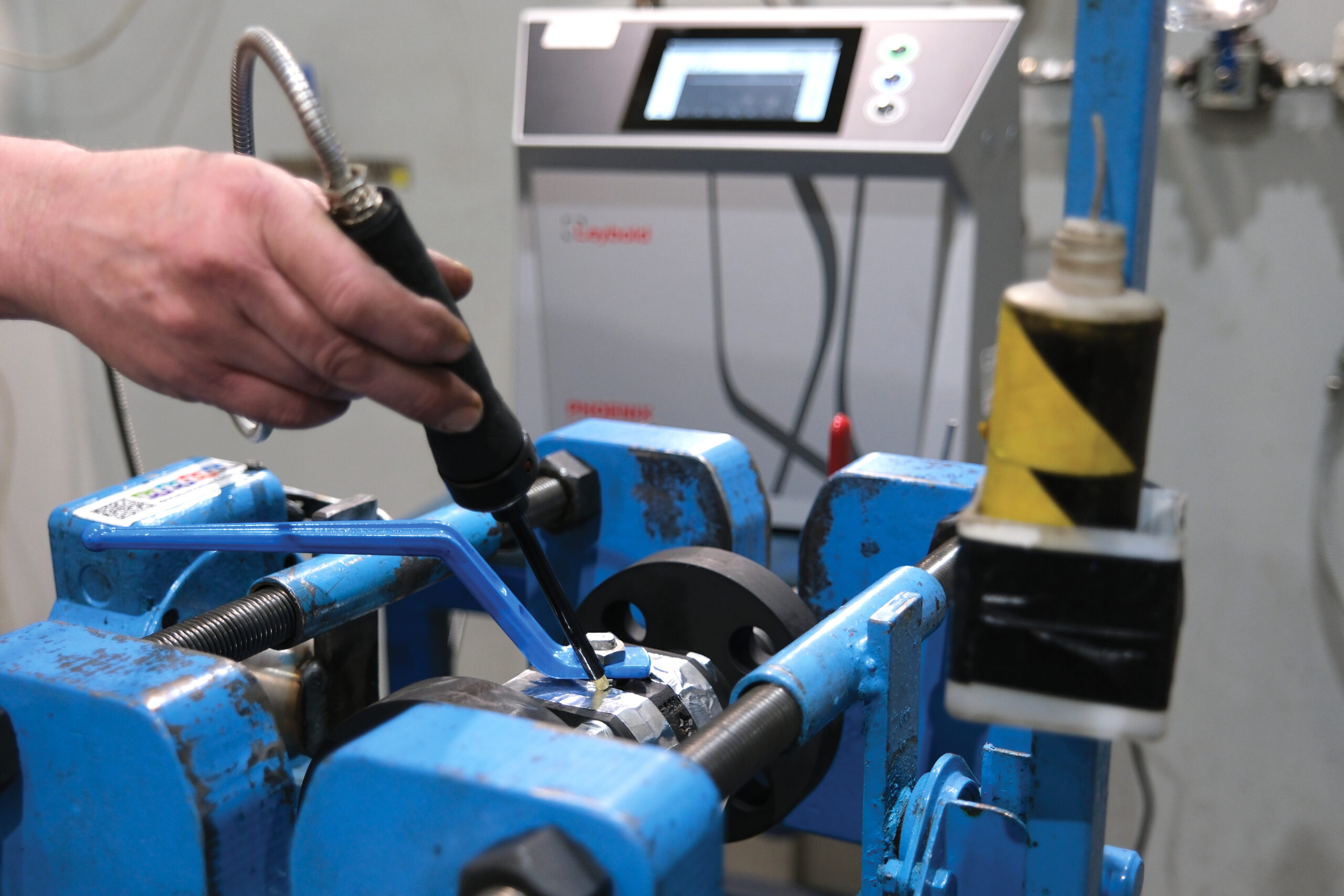

Compliance & Testing

All components undergo rigorous testing in our dedicated facilities to verify performance, integrity, and compliance. Testing regimes are selected to suit the application and may include pressure testing, leak testing, and functional verification to ensure reliability in service.

Order Management

Efficient order management is central to our process. Orders are tracked, coordinated, and fulfilled with care, ensuring correct procedures are followed, milestones are met, and operational integrity is maintained throughout.

Packing & Documentation

Each project is packed in line with customer and project requirements. Full documentation is supplied to support traceability and compliance, including certificates, test reports, and quality documentation as required

Carbon capture services

Project Supply

Valve Modification

Valve Automation

Valve Testing

Resources

View all resourcesSolving valve challenges in carbon capture

Challenge

Standard valve testing specifications call for the use of water, air and occasionally Nitrogen when testing valves.

Solution

At ACV we have invested heavily in test equipment, ranging from hydrostatic to high pressure nitrogen and on to Helium leak testing measured using our Leybold Phoenix Quadro Helium leak detector which is capable of recording leakages at extremely low levels down to 5.000 × 10⁻¹² mbar·l/s. We will shortly have available specific Hydrogen leak testing to further push the limits of leak detection.

Challenge

Elastomers and O-rings in Oil & Gas environments must meet specific requirements due to compatibility with the wide range of fluids and pressures which valves may be used on.

Solution

At ACV we hold a substantial stock of all of the main grades of HNBR, FKM and FFKM elastomers ready for installation to suit precise service requirements.

Challenge

Many of the leading Valve manufacturers have deliveries in excess of 26 weeks, some more than 52.

Solution

At ACV we hold substantial stocks of valves up to 24” and ANSI class 2500 with a variety of end connections with a number of material options. Added to this we have extensive automation and modification facilities backed up with our manufacturing capability.

We specialise in providing full scope project supply with the ability to source, expedite and inspect globally we can put together a complete scope of mixed valve and automation products from simple Gate and Globe Valves to full HiPPS packages. Our in house Projects and Engineering teams ensure full compliance and on-time delivery with full documentation.

Certainly with Ball and Butterfly valves this is normally possible with the addition of a simple interface and drive adaption to suit the valve and actuator, make sure that you specify that all such valves are supplied with an ISO mounting flange.

Standard Gate and Globe Valves are more difficult to retrospectively actuator, and this MUST be specified when enquiring or buying these products.